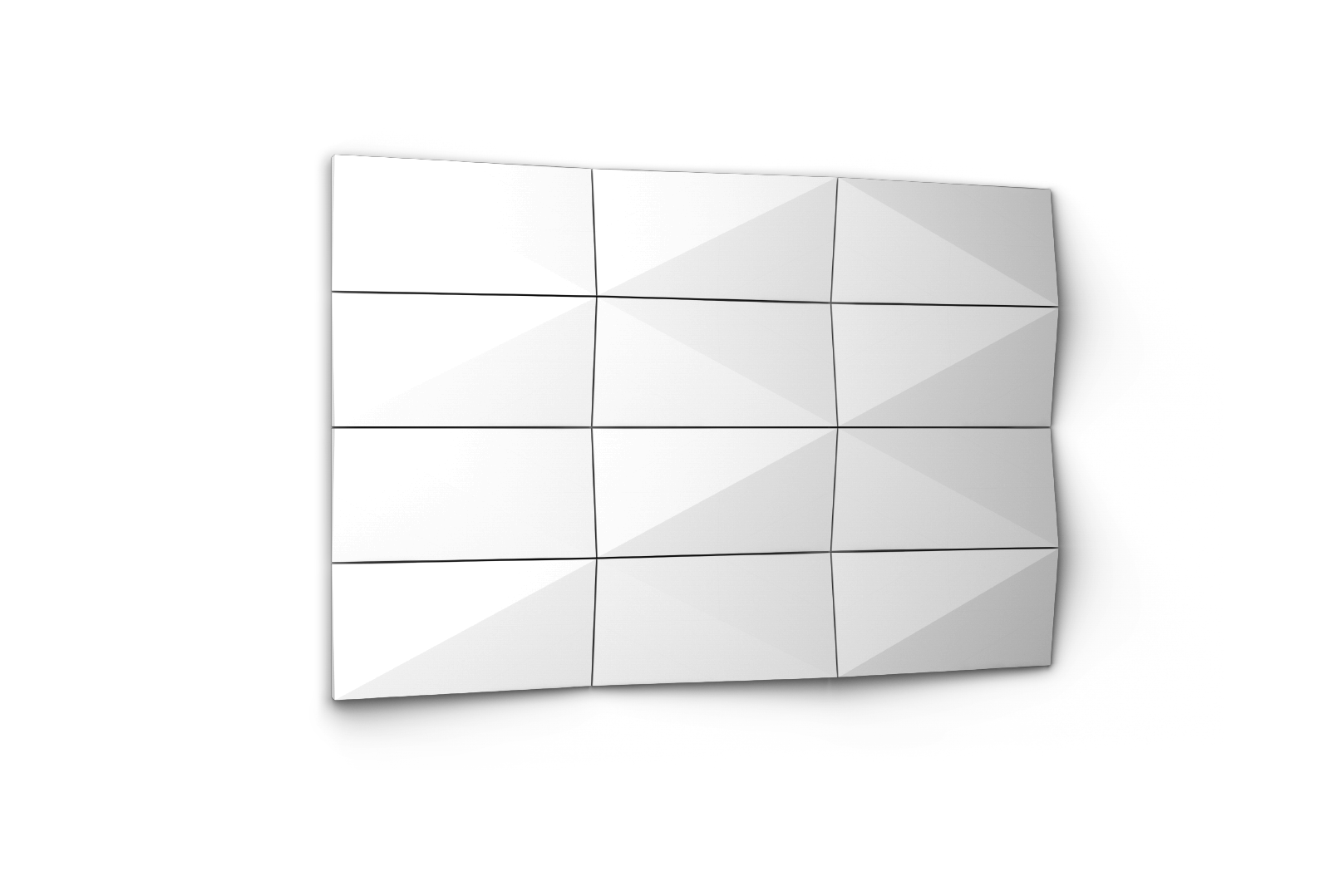

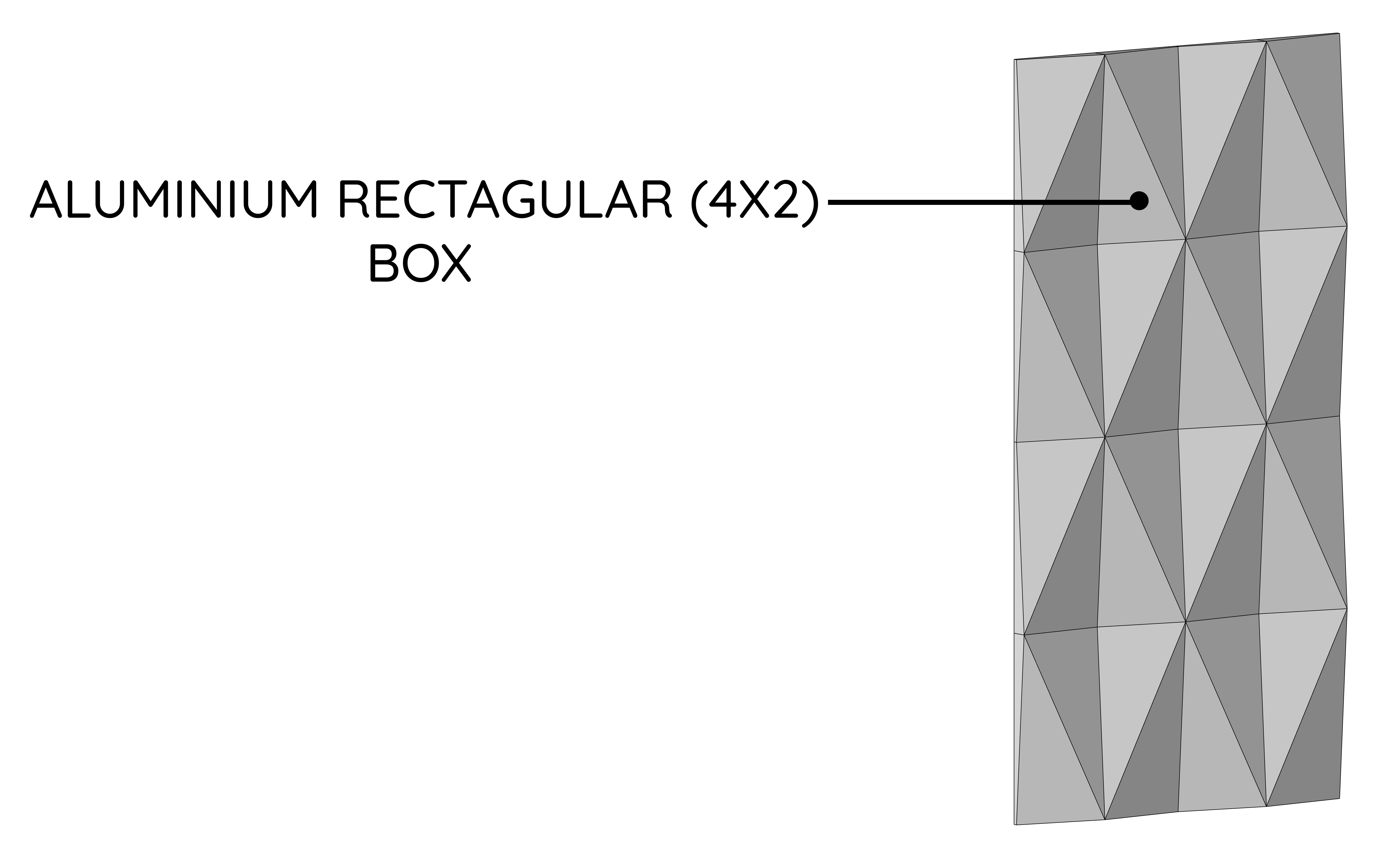

3D Panel - Wallscapes 4x2

The Wallscapes 4x2 design introduces faceted, dimensional geometry to your project, encapsulated within a sleek, long, and narrow panel. This innovative approach seamlessly integrates form and function, providing a sophisticated and contemporary element that enhances the overall aesthetic of your design.

Key Features

-

Multifaceted Architecture

Metal 3D facades provide the opportunity for elaborate and artistic architectural designs. They can be customized to form unique and attractive building exteriors, appropriate for multiple architectural styles.

-

Visual Influence

By adding depth and texture, the three-dimensional design of these facades creates a significant visual impact on the building's exterior. This can elevate the aesthetic appeal of the structure and make it more prominent.

-

Light Weight

Metal panels, being lightweight, minimize the structural strain on the building and make installation more straightforward.

-

Sustainable Development

These incorporate recycled materials, contributing to eco-friendly and sustainable building practices.

Materials & Finishes

Powder Coated Aluminum - Single Color

Aluminum

Powder Coated Aluminum - Premium Metallic Finish

Aluminum

Powder Coated Aluminum - Special Shades

Aluminum

Anodized Finish - Aluminum

AluminumHow to Specify:

-

Quoting Venture

The dedicated team in our sales support unit promptly gathers all required project data, facilitating an in-depth review of essential project variables. Our emphasis is on efficiency and precision above all else.

-

Architectural Stage

The Axes in Excess 3D Screen system is meticulously crafted and customized using our established design process. Consequently, detailed design and shop drawings are meticulously developed for your comprehensive review, feedback, and final authorization. Your active participation guarantees the delivery of a final product that seamlessly corresponds to your vision and needs.

-

Production Detailing

Upon your design approval, we engage in a meticulous process to capture every single detail. Our skilled team diligently crafts comprehensive, easily understandable, and highly specific shop drawings, ensuring precision and accuracy every step of the way. Your vision is our guiding principle, and we leave no stone unturned in bringing it to life.

-

Technical Inspection

Whether working alongside your internal engineering resources or utilizing our proficient engineering team, each Graphic Perforation project undergoes a detailed evaluation prior to manufacturing. We place importance on conducting a thorough assessment to ensure seamless integration with design specifications and project demands, thus ensuring top-quality results.

-

Modernized Manufacturing

The foundation of our precision-driven outcomes lies in our state-of-the-art facilities, advanced equipment, and skilled workforce. Through the integration of customized software solutions and the application of advanced manufacturing techniques, we ensure the delivery of precise, high-caliber products. This commitment to precision serves to benefit both you and your esteemed clients, raising the bar for the quality of your final installations.

-

Dispatch & Arrival

Throughout the entire process, our devoted team oversees every logistic aspect. Through the implementation of stringent quality control measures, we carefully organize the part crating sequence, including the arrangement of fasteners. This meticulous planning ensures the secure packaging of your product, ensuring its safe arrival at the destination and timely delivery.

-

Assembly

Transitioning you effortlessly to our network of reliable installers is our priority. Supported by our dedicated team of project managers, we'll be there every step of the way, providing support and direction. Ensuring your satisfaction and the success of your project is our main focus.