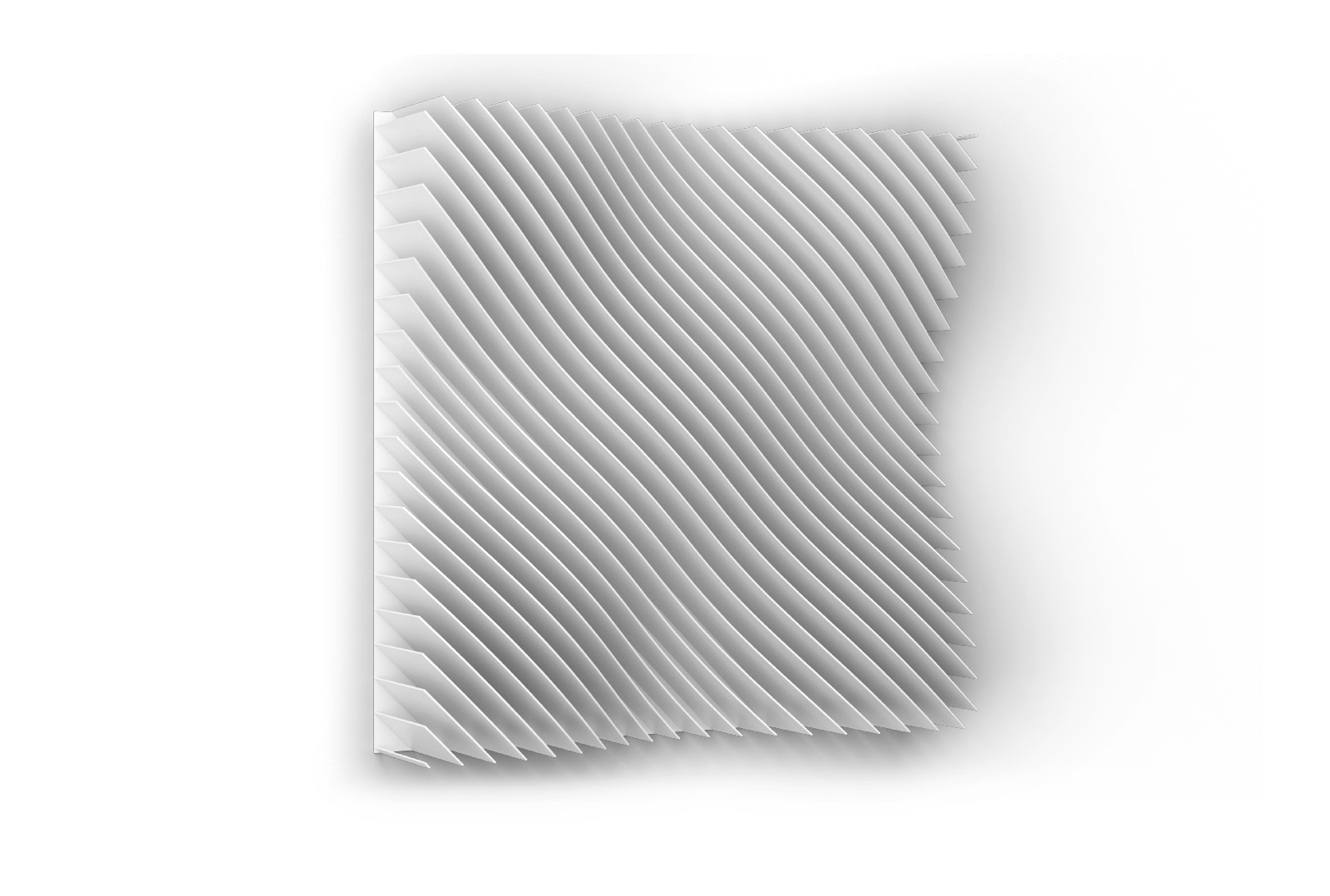

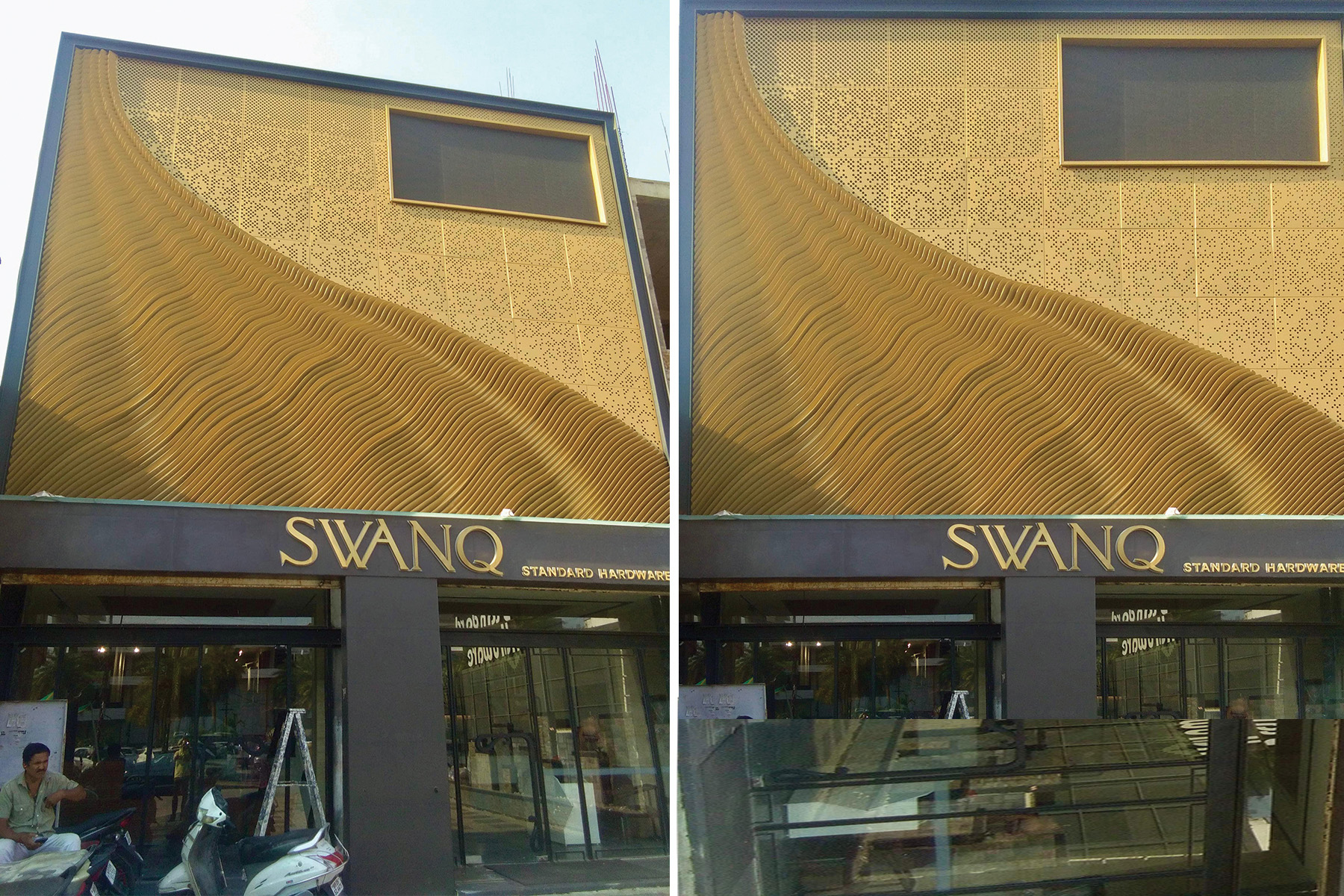

Curvaceous Facade - Diagonal

Parametric metal facade blends engineering precision and artistic expression, enabling architects to craft dynamic structures that respond intelligently to environmental needs. Seamlessly integrating technology and creativity drives architectural innovation for remarkable built environments.

Key Features

-

Flexibility within Parametric Design

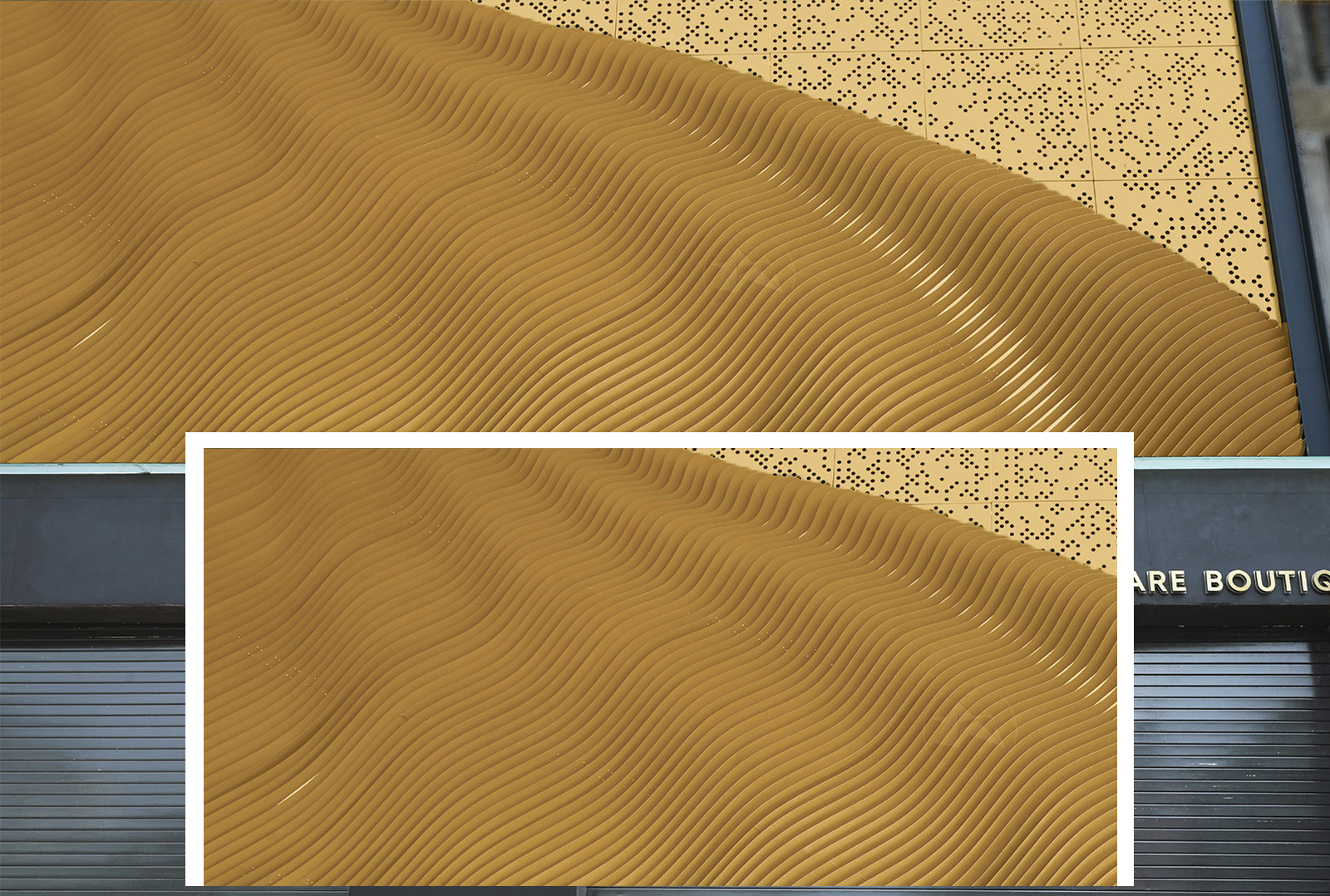

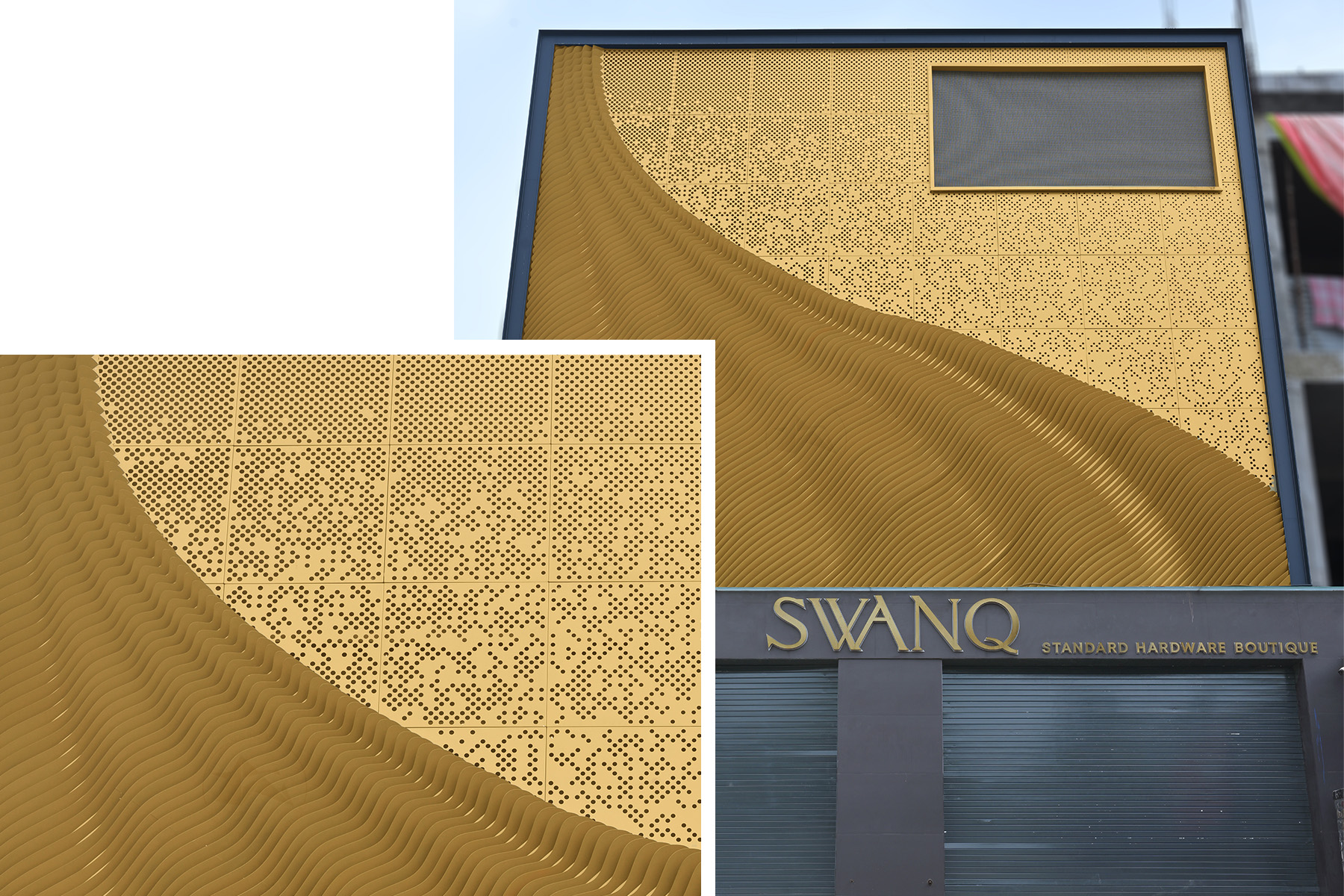

Aluminum parametric facade screens stand out for their design versatility, harnessing sophisticated principles that empower architects to fashion one-of-a-kind, tailored, and visually captivating patterns and forms.

-

Dynamic Geometry and Versatile Patterns

Utilizing parametric design, the facade screen adopts adaptable geometry, adjusting to environmental factors such as solar orientation, shading requirements, wind flow, and aesthetic considerations, thereby boosting functionality and performance.

-

Efficient Material Usage and Lightweight Building Techniques

Aluminum, being lightweight, is well-suited for facade screens, improving material efficiency without sacrificing durability. Its lightness simplifies handling and installation while lessening the structural burden on buildings.

-

Environmentally Friendly and Reusable

Aluminum, known for its sustainability and recyclability, complements eco-conscious design. Utilizing recyclable aluminum in a parametric facade screen further enhances sustainability, contributing to environmentally friendly building solutions.

Materials & Finishes

Powder Coated Aluminum - Single Color

Aluminum

Powder Coated Aluminum - Premium Metallic Finish

Aluminum

Powder Coated Aluminum - Special Shades

Aluminum

Anodized Finish - Aluminum

AluminumHow to Specify:

-

Quoting for Projects

Our dedicated sales support team promptly gathers vital project information, ensuring thorough consideration of crucial project elements. Efficiency and accuracy are paramount in every facet of our service.

-

Design Phase

The Axes Parametric system undergoes thorough customization through our established design process. Detailed design and shop drawings are meticulously created for your comprehensive review, input, and final approval, guaranteeing a product that aligns precisely with your vision and needs.

-

Detailing for Manufacturing

After your design approval, we begin a thorough process to capture every detail. Our skilled team is committed to creating comprehensive, clear, and highly detailed shop drawings, ensuring precision and accuracy throughout. Your vision leads us, and we spare no effort in bringing it to life with excellence.

-

Engineering Assessment

Whether collaborating with your in-house engineering resources or leveraging our skilled engineering team, every parametric project undergoes a thorough review before advancing to manufacturing. Our dedication to detailed evaluation guarantees exact compliance with design standards and project requirements, ensuring the delivery of high-quality results.

-

State-of-the-Art Manufacturing

Central to our commitment to precision are our state-of-the-art facilities, cutting-edge equipment, and expert staff. By incorporating custom software and advanced manufacturing techniques, we ensure the consistent delivery of precise, high-quality products. This dedication to precision not only benefits you and your valued clients but also elevates the standard of your final installations.

-

Logistics and Delivery

Throughout every stage, our committed team meticulously manages all logistics. With stringent quality control measures in place, we carefully coordinate the sequence of part crating, including fastener placement. This thorough process guarantees that your product is securely packaged and arrives at its destination intact and precisely as scheduled.

-

Deployment and Installation

We are fully equipped to coordinate a smooth connection with our network of reliable installers. With the assistance of our dedicated team of project managers, we are committed to guiding you through every phase, providing steadfast support and assistance. Your satisfaction and the success of your project are our top priorities.