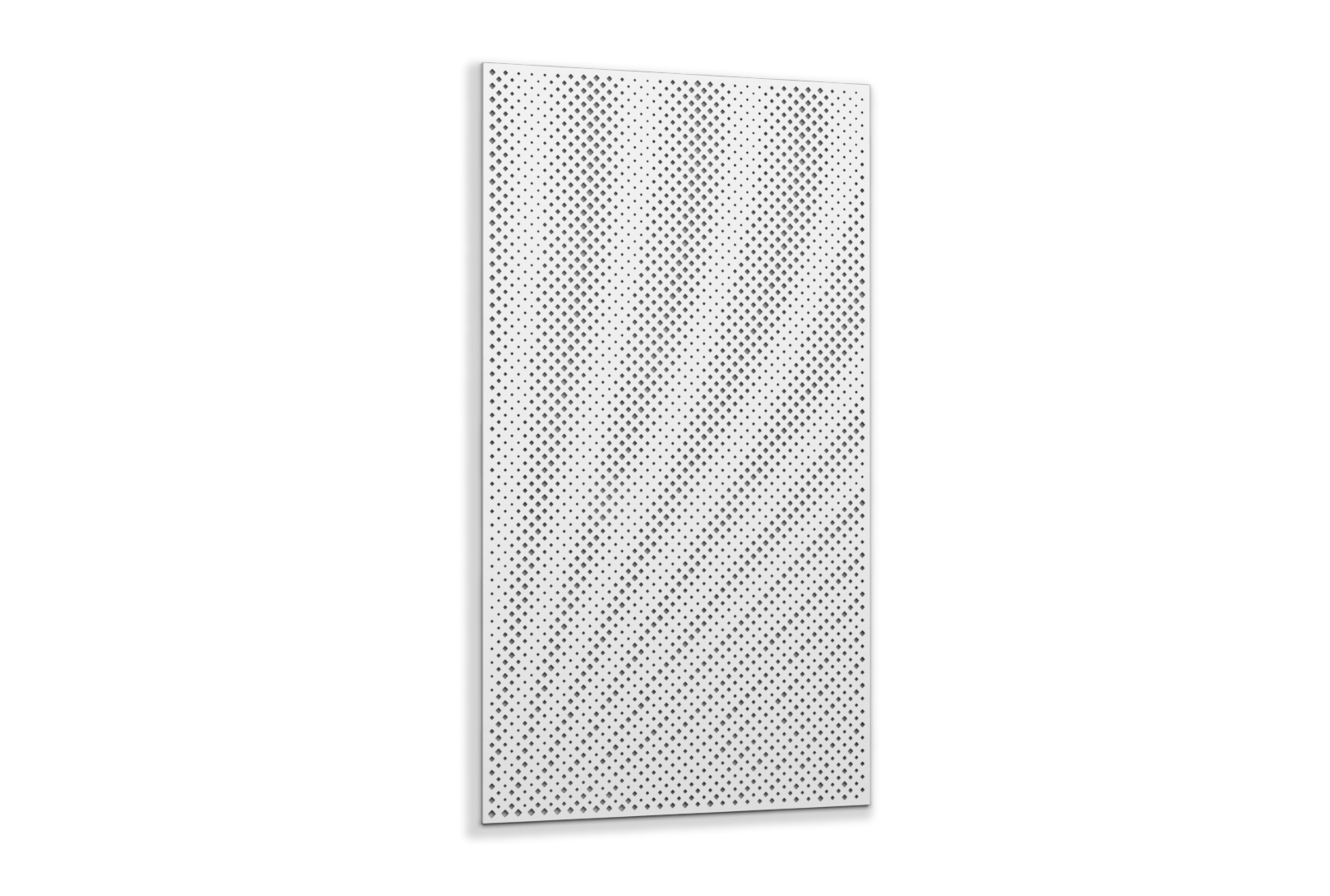

Perforation - Byte

Byte's CNC perforated panels feature square-shaped holes, turning algorithms into real-world designs. With optional integrated lighting, Byte's illuminated patterns elevate your design to the next level.

Key Features

-

Flexible and Instant Solutions

Designed for diverse criteria, Axes perforated panels offer scalable, seamlessly tileable preconfigured solutions. Choose from an expanding pattern library to effortlessly and creatively elevate your project.

-

Fluid Pattern Aesthetic: Seamless Continuity with Axes Perforated

Enjoy flawless and uninterrupted patterning with our perforated panels. Designed meticulously, the perforations wrap around edges, ensuring a seamless and sophisticated architectural canvas.

-

High-caliber Flatness and Stability: Perforation Panels

Axes panels excel in flatness and strength, leading the industry. Constructed from aluminum, our panels are 50% thicker than those of competitors, guaranteeing superior quality and longevity.

-

Smooth Illumination Integration with Axes Perforation

The Perforation line by Axes integrates InLine and Backlighting options seamlessly, blending form and function to elevate aesthetic appeal and design effectiveness.

Materials & Finishes

Powder Coated Aluminum - Single Color

Aluminum

Powder Coated Aluminum - Premium Metallic Finish

Aluminum

Powder Coated Aluminum - Special Shades

Aluminum

Powder Coated Aluminum - Premium Wood Textures

Aluminum

Anodized Finish - Aluminum

AluminumHow to Specify:

-

Quote Crafting Task

The dedicated sales support team acts promptly to gather all necessary project data, ensuring a thorough consideration of critical project factors. Efficiency and precision are our guiding principles.

-

Prototype Phase

The Axes Frequency Perforation system is meticulously adapted and personalized using our time-tested design methodology. Subsequently, detailed design and shop drawings are meticulously developed, welcoming your comprehensive review, feedback, and final approval. Your engagement guarantees the production of a final product that perfectly corresponds to your vision and requirements.

-

Manufacturing Blueprinting

Upon your design endorsement, we initiate a thorough process to encapsulate each final detail. Our proficient team diligently generates comprehensive, easily interpretable, and exceedingly detailed shop drawings, ensuring meticulousness and accuracy throughout the process. Your vision guides our efforts, and we spare no endeavor in transforming it into tangible brilliance.

-

Engineering Audit

Whether collaborating with your in-house engineering capabilities or leveraging our skilled engineering team, each Graphic Perforation project undergoes a thorough assessment prior to manufacturing. We prioritize a meticulous evaluation to ensure precise alignment with design specifications and project requirements, ensuring the delivery of the highest quality outcomes.

-

Contemporary Production

Precision is the cornerstone of our operations, facilitated by our state-of-the-art facilities, cutting-edge equipment, and experienced workforce. Through the utilization of custom software and advanced manufacturing processes, we guarantee the delivery of precise, high-caliber products. This commitment to precision benefits both you and your esteemed clients, raising the standard of your completed installations.

-

Cargo and Receipt

Our dedicated team manages every logistical detail from initiation to completion. Employing strict quality control measures, we intricately organize the part crating sequence, including the placement of fasteners. This meticulous approach guarantees the safe packaging of your product and its timely delivery according to the schedule.

-

Incorporation

We're prepared to effortlessly unite you with our network of esteemed installers. Our dedicated team of project managers will be there to assist you, offering support and direction throughout your journey. Your contentment and the triumph of your project are our foremost concerns.