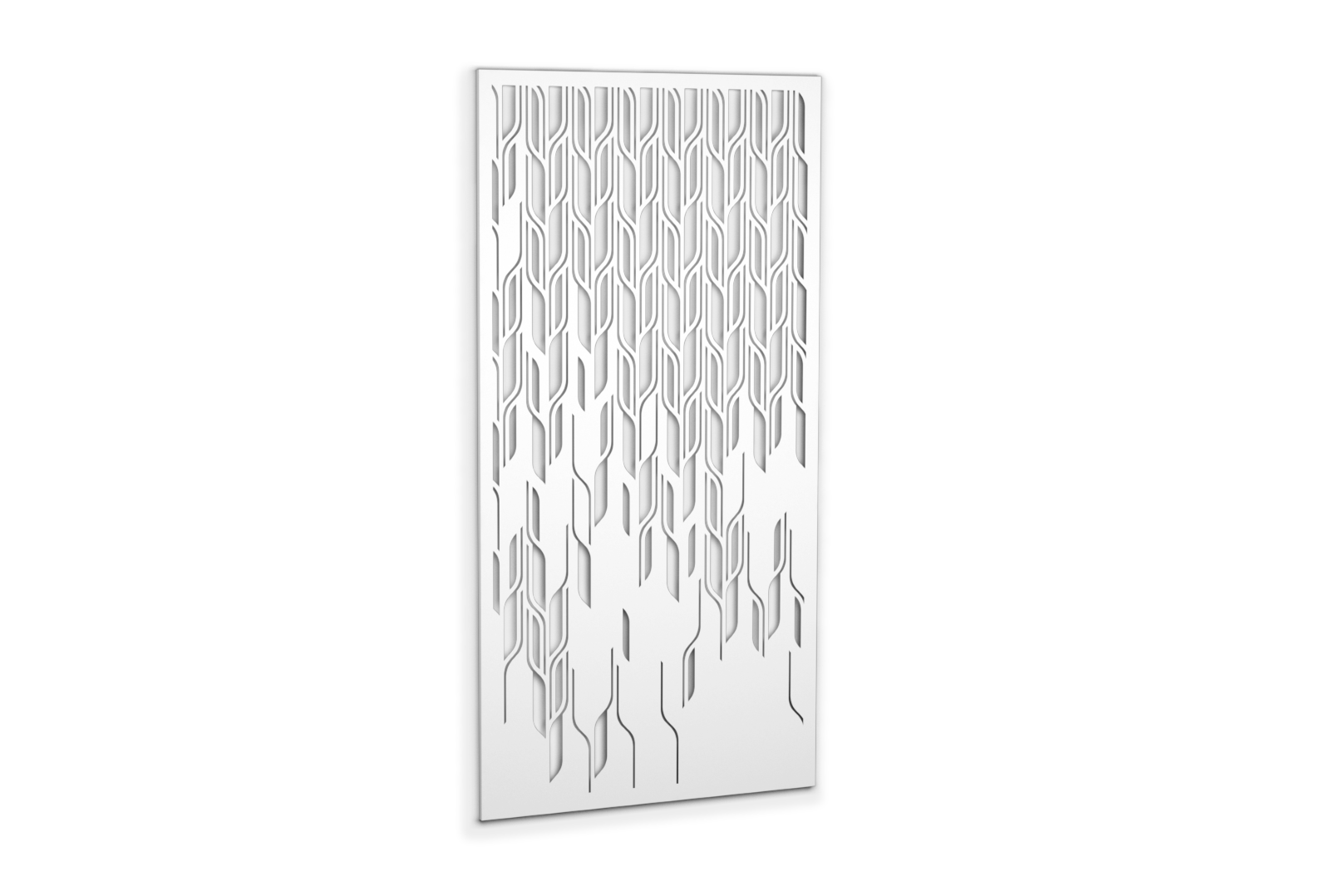

Perforation - Crown

levate your space with regal precision. Meticulously crafted patterns create a sophisticated ambiance, combining luxury and functionality seamlessly.

Key Features

-

Unmatched Flatness and Robustness: Perforation Panels

Renowned for exceptional flatness and strength, Axes panels set an industry benchmark. Constructed from aluminum, they are 50% thicker than competing panels, guaranteeing superior quality and longevity.

-

Seamlessly Integrated Lighting with Axes Perforation

With InLine and Backlighting options, Axes's Perforation line blends lighting seamlessly into projects, elevating both form and function for a striking aesthetic impact.

-

Adaptable and Pre-Packaged Solutions

Providing scalable, seamlessly tileable preconfigured solutions, Axes perforated panels are designed for a range of criteria. Choose from an expanding pattern library to creatively and effortlessly elevate your project.

-

Unbroken Patterning: The Flowing Pattern Aesthetic with Axes Perforated

Our meticulously designed perforated panels offer uninterrupted patterning in your space. The perforations elegantly wrap around the edges, ensuring seamless continuity for a refined architectural canvas.

Materials & Finishes

Powder Coated Aluminum - Single Color

Aluminum

Powder Coated Aluminum - Premium Metallic Finish

Aluminum

Powder Coated Aluminum - Special Shades

Aluminum

Powder Coated Aluminum - Premium Wood Textures

Aluminum

Anodized Finish - Aluminum

AluminumHow to Specify:

-

Quotation Quest

The dedicated sales support unit swiftly collects all requisite project information, facilitating a meticulous examination of pivotal project components. Our priority lies in efficiency and precision.

-

Planning Phase

Our tailored design process ensures the meticulous customization of the Axes Crown Perforation system. Detailed design and shop drawings are subsequently meticulously developed, inviting your thorough review, feedback, and ultimate approval. Your engagement guarantees the delivery of a final product that perfectly reflects your vision and needs.

-

Fabrication Description

Upon receiving your design endorsement, we embark on a meticulous journey to encapsulate each final nuance. Our proficient team works assiduously to generate comprehensive, easily comprehensible, and highly detailed shop drawings, ensuring meticulousness and accuracy at every juncture. Your vision serves as our North Star, and we meticulously translate it into tangible brilliance.

-

Technical Assessment

Whether engaging with your internal engineering expertise or utilizing our adept engineering squad, each Graphic Perforation project undergoes a detailed scrutiny pre-manufacturing. Our focus lies on a thorough examination to assure seamless adherence to design specifications and project demands, securing superior quality results.

-

State-of-the-Art Manufacturing

The cornerstone of our precision-driven outcomes lies in our state-of-the-art facilities, cutting-edge equipment, and highly skilled personnel. By incorporating customized software solutions and implementing advanced manufacturing techniques, we ensure the delivery of meticulous, top-tier products. This commitment to precision not only benefits you and your esteemed clients but also enhances the overall standard of your completed installations.

-

Shipping and Distribution

Throughout the entire process, our dedicated team takes charge of every logistics detail. By enforcing strict quality control standards, we carefully organize the part crating order, right down to the arrangement of fasteners. This thorough approach ensures that your product is safely packed and arrives at its destination without any damage, precisely as scheduled.

-

Assembly

We're prepared to smoothly facilitate your connection with our network of dependable installers. Our dedicated team of project managers will stand by your side, furnishing support and counsel during your venture. Your satisfaction and the triumph of your project rank highest on our list of priorities.