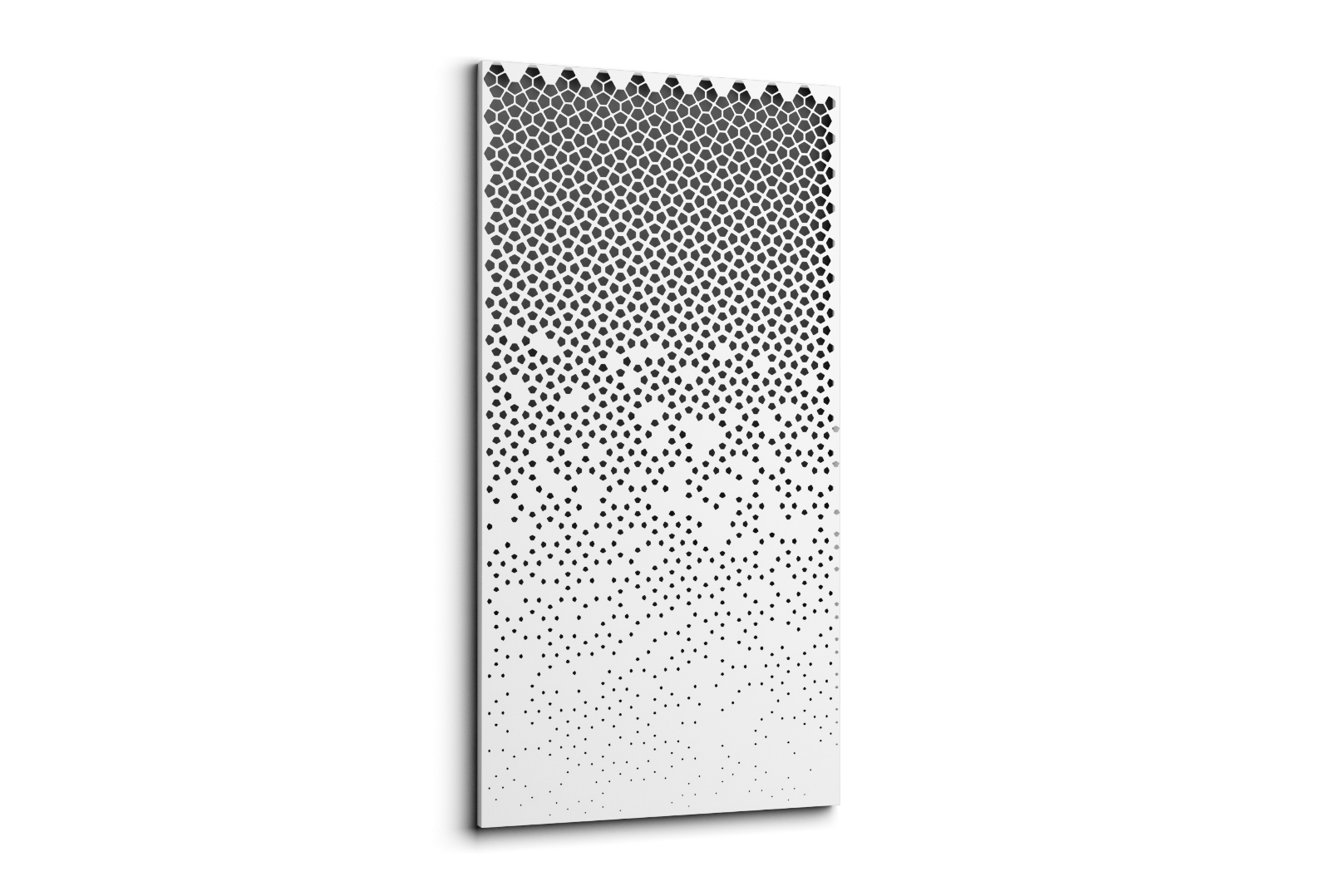

Perforation - Gradiant

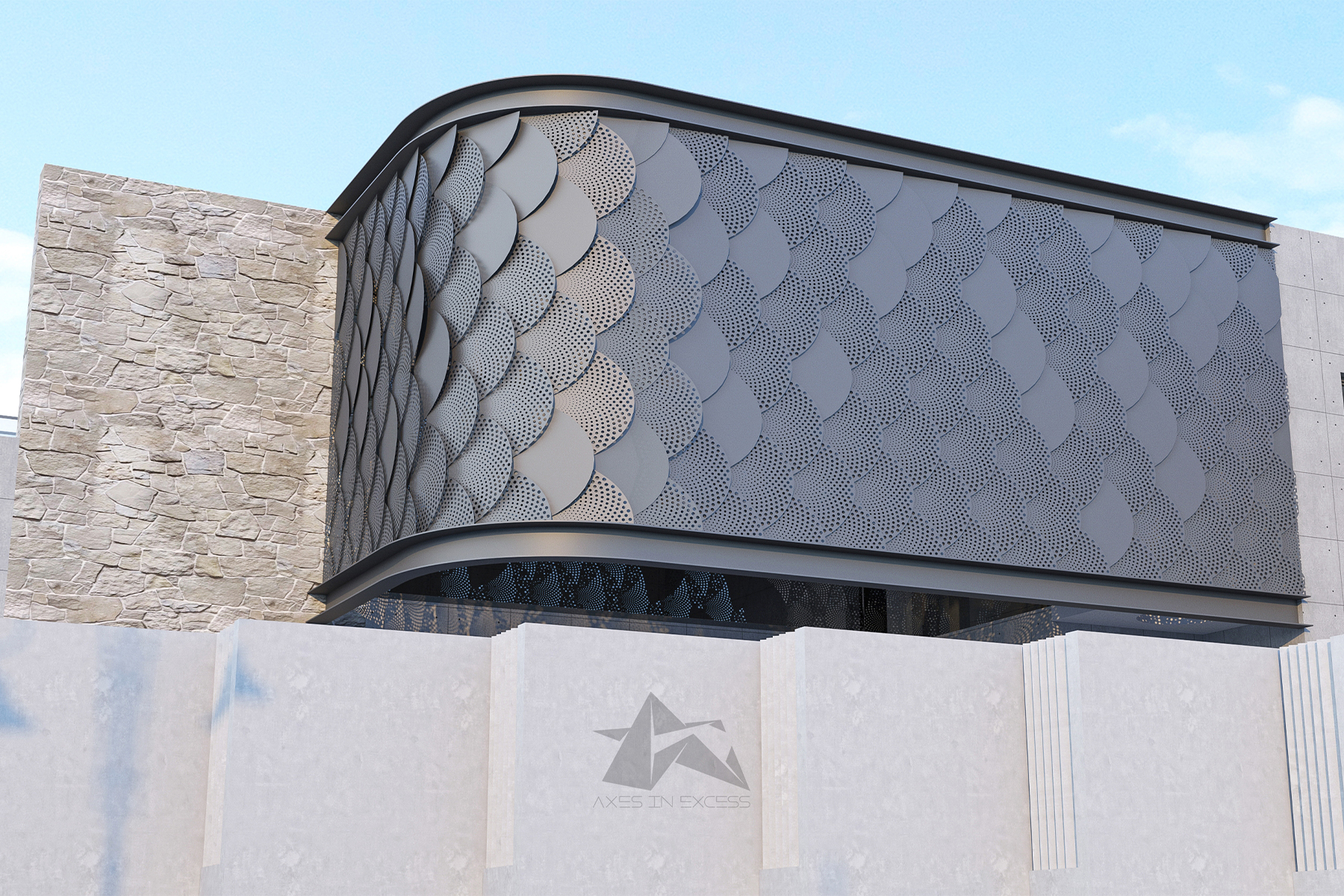

Discover innovative Gradian CNC perforation in metal solutions by Axes in Excess. Designed for metal facades and metal cladding projects, our customizable options provide endless design possibilities for architects and designers.

Key Features

-

Prime Flatness and Toughness: Perforation Panels

Known for superior flatness and strength, Axes panels set the industry standard. Made from aluminum and 50% thicker than competitors, they ensure unparalleled quality and durability.

-

Seamless Light Integration with Axes Perforation

With seamless integration of InLine and Backlighting, Axes's Perforation line enhances projects by merging form and function, elevating aesthetic appeal and impact.

-

All-Inclusive and Ready-to-Use Solutions

Scalable and seamlessly tileable, Axes perforated panels provide preconfigured solutions for varied criteria. Enhance your project creatively and effortlessly by selecting from an expanding pattern library.

-

Seamless Design: Continuous Pattern Beauty with Axes Perforated

Create an uninterrupted patterning effect with our meticulously designed perforated panels. Perforations wrap elegantly around edges, providing seamless continuity for a sophisticated architectural look.

Materials & Finishes

Powder Coated Aluminum - Single Color

Aluminum

Powder Coated Aluminum - Premium Metallic Finish

Aluminum

Powder Coated Aluminum - Special Shades

Aluminum

Powder Coated Aluminum - Premium Wood Textures

Aluminum

Anodized Finish - Aluminum

AluminumHow to Specify:

-

Costing Conception

With speed and diligence, our dedicated sales support team compiles all necessary project data, enabling a detailed review of essential project factors. Efficiency and precision are paramount.

-

Conceptualization Stage

The Axes Gradiant Perforation system undergoes meticulous customization through our established design process. Detailed design and shop drawings are meticulously generated subsequently, allowing for your thorough review, contribution, and final approval. Your active involvement guarantees the creation of a final product that perfectly aligns with your vision and preferences.

-

Production Blueprinting

Upon the approval of your design, we undertake a meticulous process to encapsulate every final detail. Our proficient team diligently produces comprehensive, easily comprehensible, and highly detailed shop drawings, ensuring precision and accuracy throughout the endeavor. Your vision propels our journey, and we meticulously translate it into tangible greatness.

-

Design Evaluation

Whether partnering with your internal engineering resources or utilizing our proficient engineering team, each Graphic Perforation project undergoes a meticulous evaluation prior to manufacturing commencement. We prioritize a thorough assessment to ensure perfect alignment with design specifications and project requirements, guaranteeing superior quality outcomes.

-

Futuristic Fabrication

Precision is paramount in our operations, supported by our state-of-the-art facilities, cutting-edge technology, and expert personnel. Through the utilization of custom software and advanced manufacturing methods, we guarantee the provision of precise, high-quality products. This commitment to precision not only benefits you and your clients but also enhances the excellence of your completed installations.

-

Consignment and Drop-off

From beginning to end, our dedicated team oversees all logistics with precision. By enforcing strict quality control measures, we meticulously plan the part crating sequence, down to the exact placement of fasteners. This meticulous process ensures the safe packaging of your product, ensuring it arrives at its destination on schedule and intact.

-

Integration

We're prepared to smoothly link you with our network of dependable installers. Our dedicated team of project managers will stand by your side, offering assistance and advice throughout your experience. Your contentment and project prosperity are our primary objectives.