Perforation - Graphics

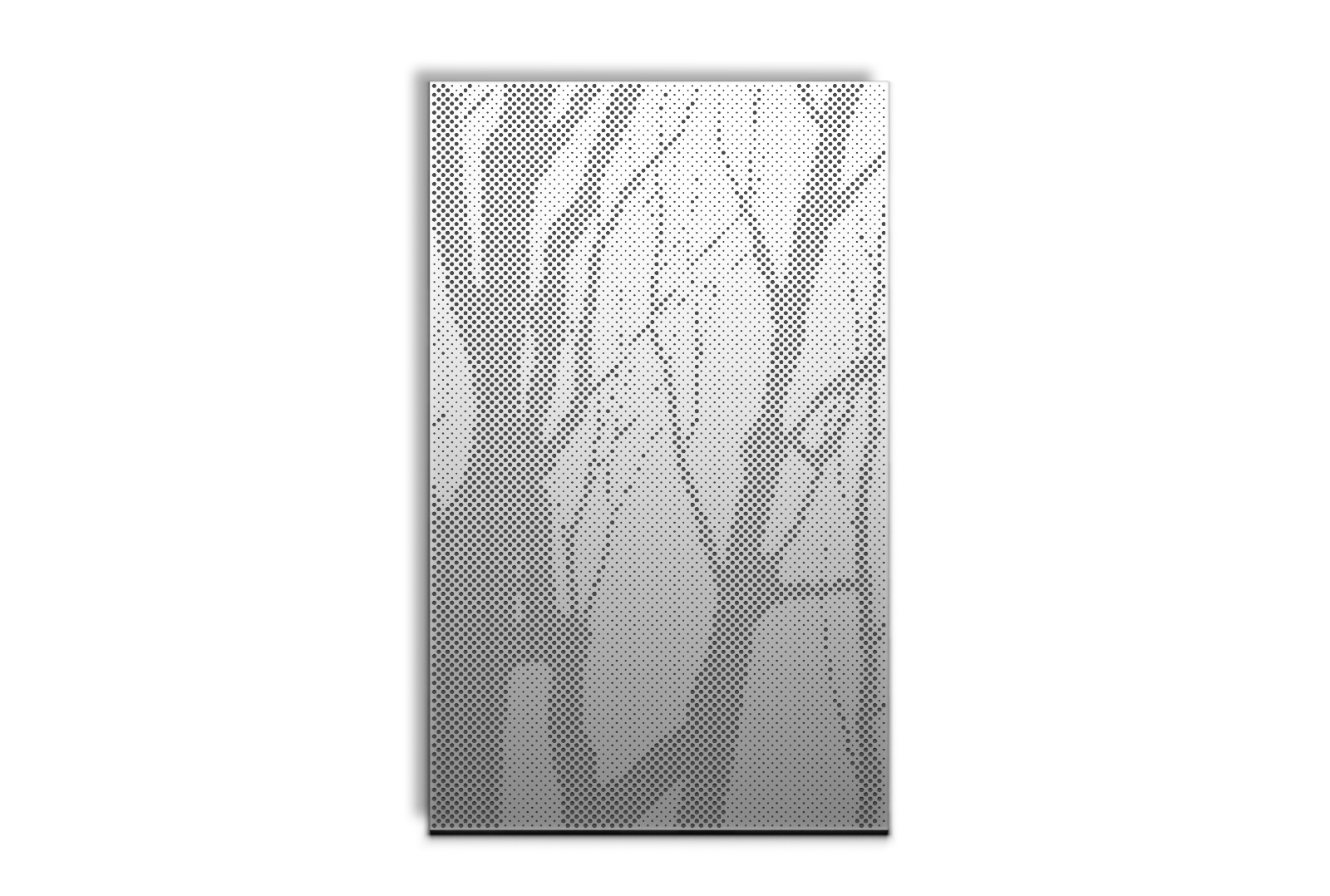

Ever envisioned turning an image or a unique pattern into a captivating display using perforated metal panels? Look no further. Graphic Perforation Solutions offers you two dynamic pathways: Photoreal and Scripted. Regardless of your choice, your design is meticulously deconstructed into modular segments, seamlessly converging to form a stunning whole. Our flexible attachments, tailored to your space's unique requirements, ensure a flawless installation. At Axes, our team of experts stands ready to assist you in creating a truly distinctive look, setting both you and your design apart from the ordinary.

Key Features

-

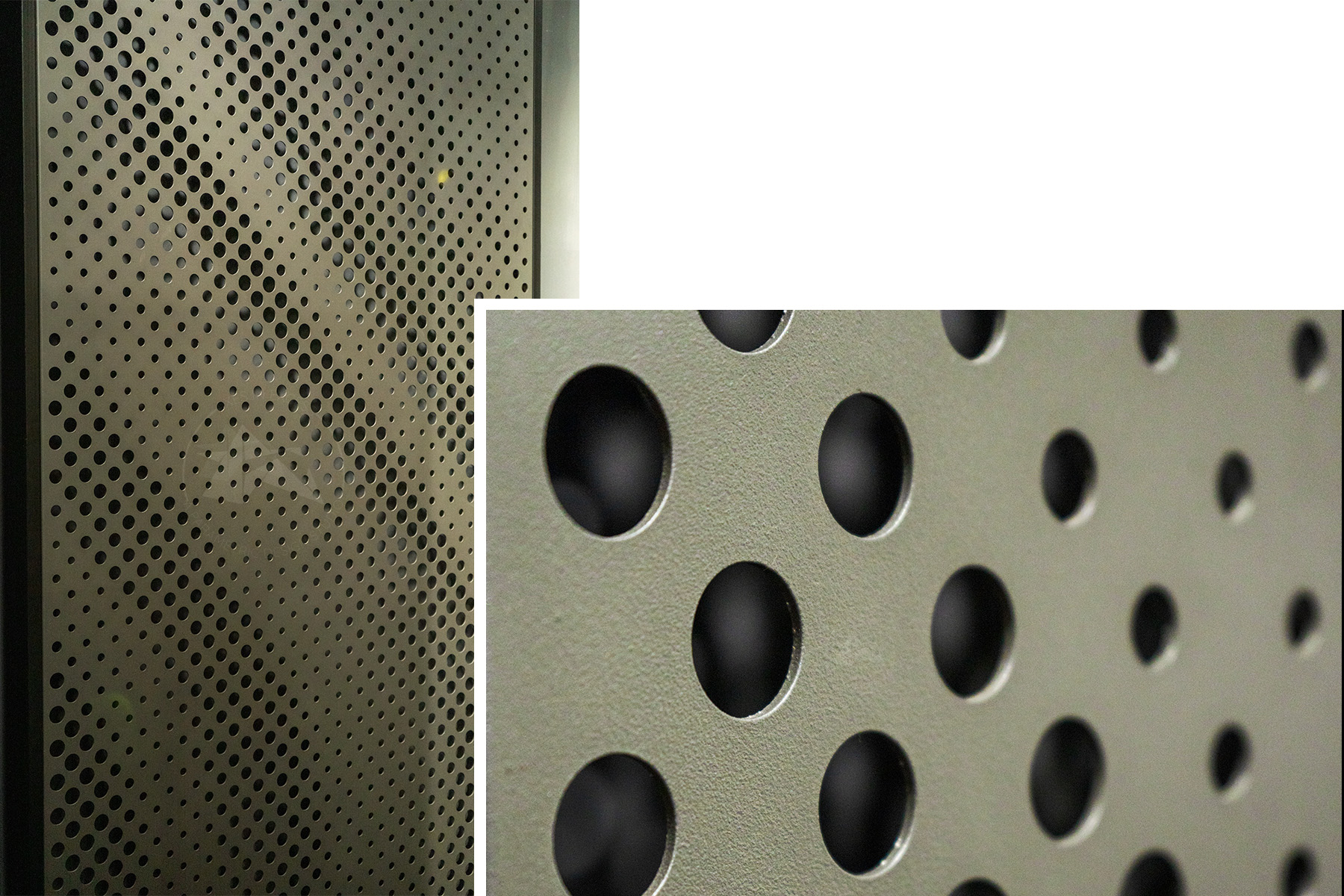

Superior Flatness and Durability: Perforation Panels

Axes panels lead the industry in flatness and strength. Made from aluminum, our panels boast 50% greater thickness than competitors, ensuring unparalleled quality and durability.

-

Perfect Illumination Integration with Axes Perforation

Axes's Perforation line integrates lighting seamlessly with InLine and Backlighting options, harmonizing form and function to enhance aesthetic appeal and design impact.

-

Flexible and Turnkey Solutions

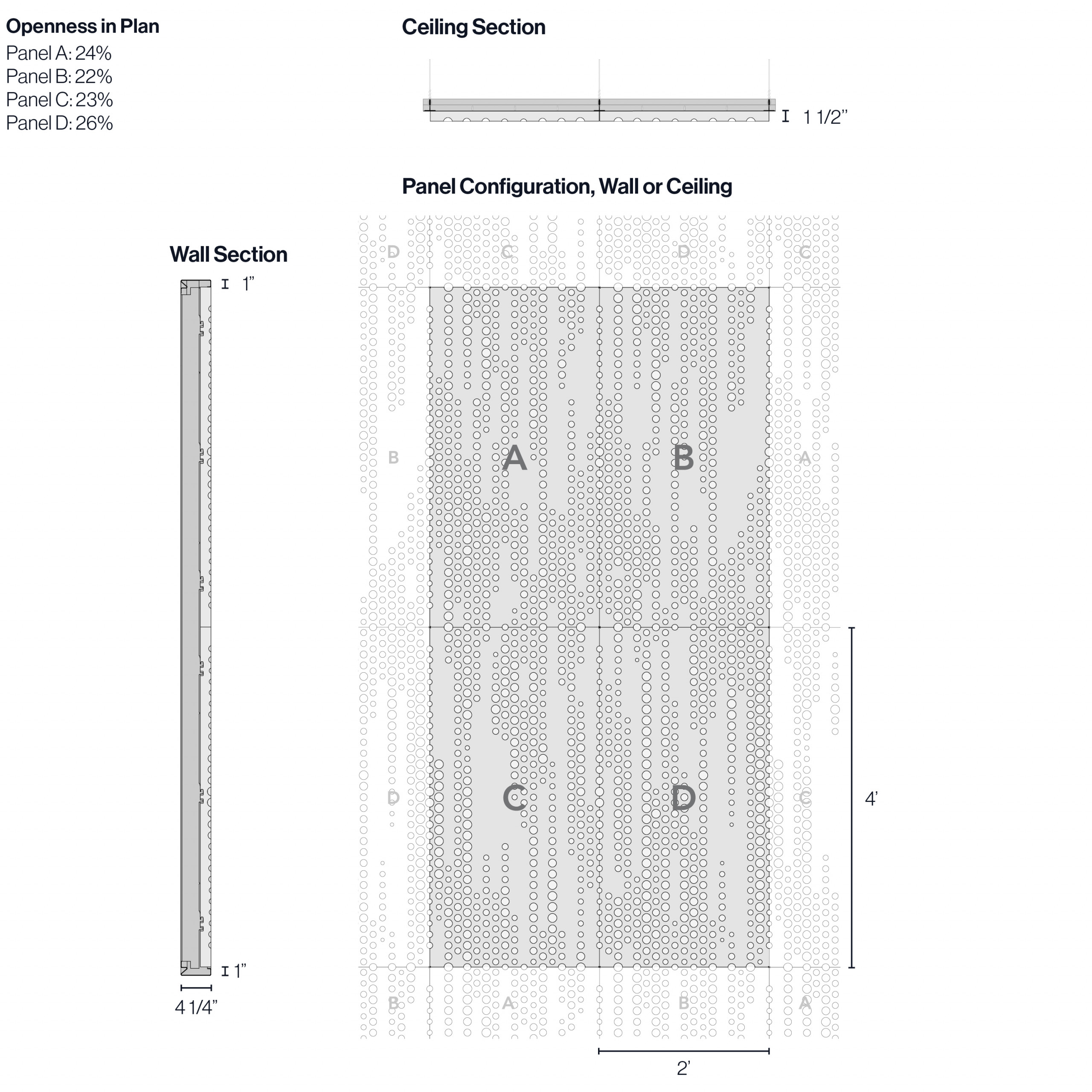

Axes perforated panels offer scalable, tileable preconfigured solutions tailored to various criteria. Select from a growing pattern library to enhance your project with creativity and ease.

-

Fluid Design: Continuous Pattern Elegance with Axes Perforated

Experience flawless patterning with our expertly designed perforated panels. The perforations gracefully wrap around edges, creating a seamless continuity for an elegant architectural canvas.

Materials & Finishes

Powder Coated Aluminum - Single Color

Aluminum

Powder Coated Aluminum - Premium Metallic Finish

Aluminum

Powder Coated Aluminum - Special Shades

Aluminum

Powder Coated Aluminum - Premium Wood Textures

Aluminum

Anodized Finish - Aluminum

AluminumHow to Specify:

-

Estimation Endeavor

Our committed sales support squad promptly assembles all necessary project details, facilitating a comprehensive review of vital project elements. Efficiency and accuracy remain our foremost focus.

-

Development Phase

The Axes Graphic Perforation system undergoes meticulous customization through our well-honed design methodology. Following this, comprehensive design and shop drawings are meticulously prepared for your careful examination, input, and final endorsement. Your active participation guarantees a final product that precisely matches your vision and specifications.

-

Production Specification

Upon securing your design approval, we undertake a thorough process to capture every last detail. Our adept team labors diligently to produce thorough, user-friendly, and exceedingly precise shop drawings, guaranteeing exactitude and correctness throughout. Your vision serves as our compass, and we spare no effort in manifesting it into palpable greatness.

-

Engineering Evaluation

Whether partnering with your internal engineering capabilities or utilizing our proficient engineering team, every Graphic Perforation project undergoes a rigorous assessment prior to production. We emphasize a meticulous evaluation to ensure perfect harmony with design parameters and project needs, ensuring top-tier results.

-

Cutting-Edge Production

Our modern facilities, top-of-the-line machinery, and expert workforce form the foundation of precision-driven results. Through the integration of bespoke software and the utilization of advanced manufacturing methods, we guarantee the provision of accurate, premium-grade products. This dedication to precision not only enhances your satisfaction but also raises the bar for the final installation quality.

-

Transportation and Delivery

From start to finish, our committed team oversees all logistical elements. Implementing rigorous quality control protocols, we meticulously arrange the part crating sequence, including the positioning of fasteners. This detailed method ensures your product is securely packaged and reaches its destination intact and precisely on time.

-

Mounting

We stand prepared to effortlessly link you with our roster of reliable installers. Our committed team of project managers will accompany you every step of the way, offering assistance and direction throughout your experience. Your contentment and project prosperity remain at the forefront of our concerns.