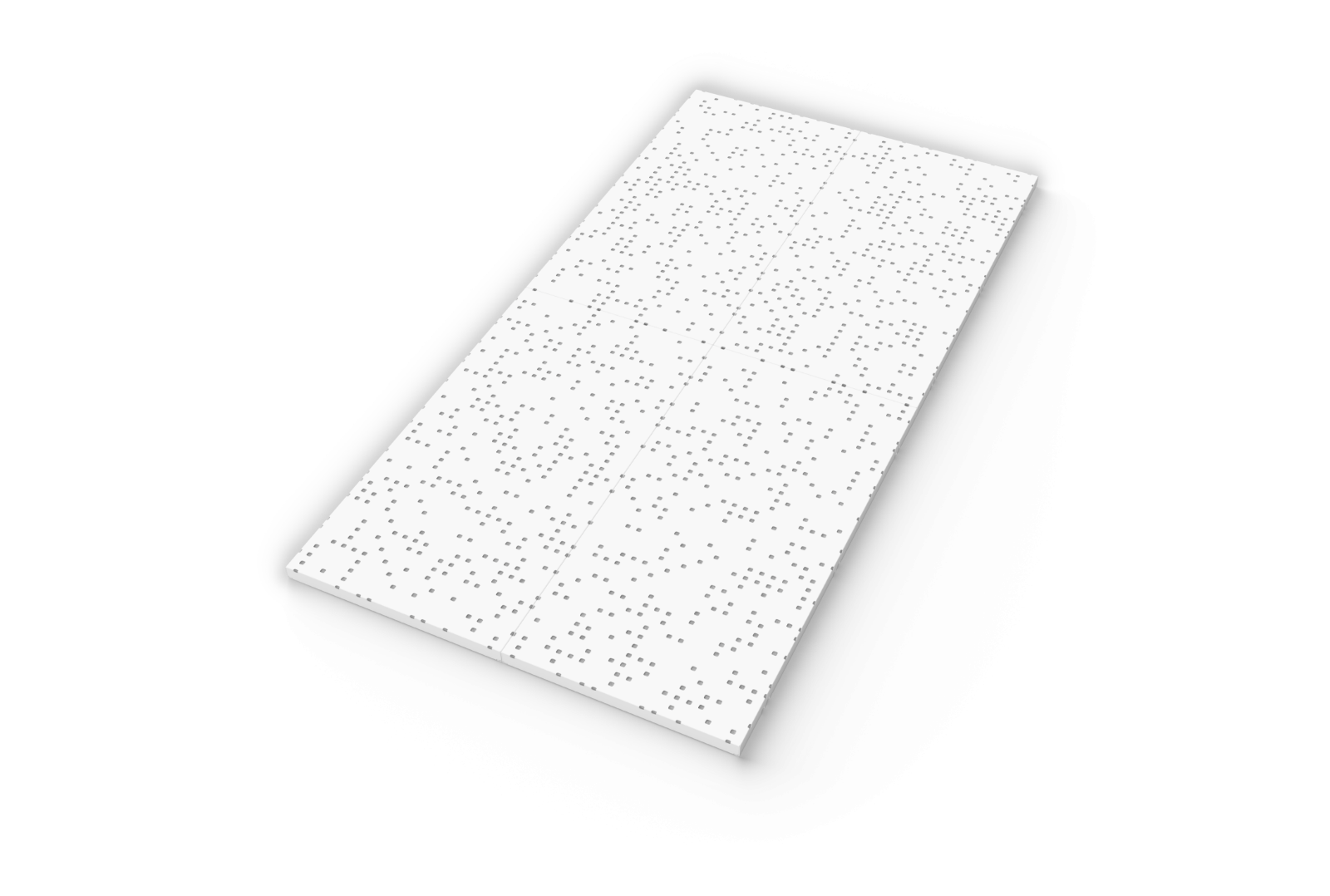

Perforation - Shift X

Shift X powder-coated aluminum CNC perforated panels layer nature-inspired patterns, adding an organic quality that emulates natural growth. Layering differently sized patterns creates depth and interest.

Key Features

-

Exceptional Flatness and Integrity: Perforation Panels

Leading the way in flatness and strength, Axes panels set a high industry standard. Made from aluminum, they are 50% thicker than competitor panels, ensuring exceptional quality and durability.

-

Cohesive Lighting Integration with Axes Perforation

Axes's Perforation line effortlessly integrates lighting with InLine and Backlighting, enhancing projects by combining form and function for greater aesthetic impact.

-

Adaptable and Off-the-Shelf Solutions

Axes perforated panels offer scalable, tileable preconfigured solutions for various criteria. Enhance your project creatively and effortlessly by choosing from our expanding pattern library.

-

Continuous Flow: The Seamless Pattern Aesthetic with Axes Perforated

Our perforated panels, designed for uninterrupted patterning, feature perforations that wrap elegantly around edges, ensuring seamless continuity for a refined architectural canvas.

Materials & Finishes

Powder Coated Aluminum - Single Color

Aluminum

Powder Coated Aluminum - Premium Metallic Finish

Aluminum

Powder Coated Aluminum - Special Shades

Aluminum

Powder Coated Aluminum - Premium Wood Textures

Aluminum

Anodized Finish - Aluminum

AluminumHow to Specify:

-

Project Evaluation for Pricing

Our dedicated sales support team swiftly collects all essential project data, facilitating a meticulous examination of vital project factors. Efficiency and precision remain our primary objectives.

-

Initial Design Phase

Through our proven design process, the Axes Byte Perforation system undergoes meticulous customization and tailoring. Detailed design and shop drawings are then meticulously prepared, inviting your careful examination, input, and ultimate authorization. Your involvement ensures the delivery of a final product that precisely aligns with your vision and specifications.

-

Production Documentation

Upon receiving your design confirmation, we embark on a meticulous journey to encompass every final aspect. Our skilled team meticulously crafts comprehensive, user-friendly, and highly specific shop drawings, ensuring precision and accuracy in every facet. Your vision serves as our guiding principle, and we meticulously translate it into tangible perfection.

-

Design Assessment

Whether engaging with your internal engineering expertise or utilizing our proficient engineering squad, every Graphic Perforation project is subjected to a comprehensive review before manufacturing begins. Our focus lies on conducting a detailed assessment to assure perfect harmony with design parameters and project needs, securing superior quality results.

-

Progressive Manufacturing

Our unwavering commitment to precision is supported by our advanced facilities, top-tier equipment, and skilled workforce. By incorporating custom software solutions and employing advanced manufacturing techniques, we ensure the production of accurate, premium-quality products. This dedication to precision not only meets your expectations but also enhances the overall standard of your final installations.

-

Transport and Handover

From start to finish, our committed team takes care of all logistical aspects. Implementing stringent quality control measures, we meticulously plan the part crating sequence, right down to the positioning of fasteners. This careful approach ensures that your product is securely packed and arrives at its destination without any damage, exactly on schedule.

-

Deployment

We're ready to smoothly facilitate your connection with our roster of trusted installers. Our dedicated team of project managers will be by your side, providing support and guidance throughout your experience. Ensuring your satisfaction and the success of your project are our primary goals.