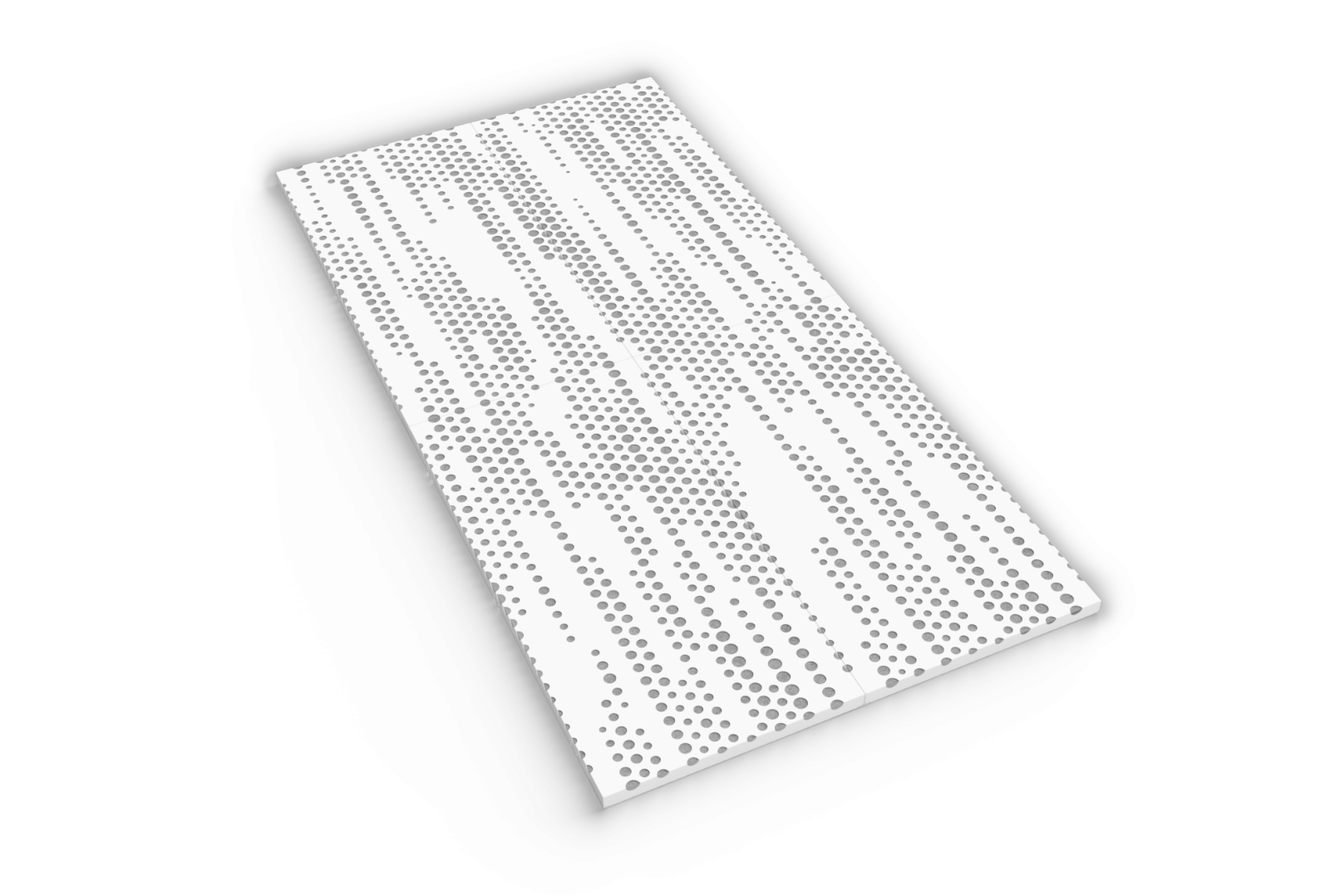

Perforation - Sky

Experience the allure of our Sky powder-coated aluminum panels, adorned with a linear arrangement of various-sized circles, yielding a fluid, emotive impact. Each sequence culminates with diminutive circles, crafting a captivating skyscape that beckons exploration.

Key Features

-

Versatile and Pre-Configured Solutions

Axes perforated panels feature scalable, tileable preconfigured solutions designed for diverse needs. Elevate your project creatively and effortlessly with our expanding pattern library.

-

Endless Pattern Flow: The Continuous Aesthetic with Axes Perforated

Our expertly crafted perforated panels deliver uninterrupted patterning in your space. The perforations gracefully wrap around edges, ensuring a seamless and sophisticated architectural canvas.

-

Leading Flatness and Endurance: Perforation Panels

Axes panels are distinguished by their flatness and strength, setting a new industry benchmark. Crafted from aluminum, they are 50% thicker than competitor panels, ensuring top-tier quality and durability.

-

Integrated Illumination with Axes Perforation

InLine and Backlighting options in Axes's Perforation line seamlessly merge form and function, enhancing the aesthetic and design impact of projects.

Materials & Finishes

Powder Coated Aluminum - Single Color

Aluminum

Powder Coated Aluminum - Premium Metallic Finish

Aluminum

Powder Coated Aluminum - Special Shades

Aluminum

Powder Coated Aluminum - Premium Wood Textures

Aluminum

Anodized Finish - Aluminum

AluminumHow to Specify:

-

Rate Calculation Initiative

Our dedicated sales support team moves swiftly to collect all essential project data, facilitating a thorough examination of critical project factors. Efficiency and precision are our primary concerns.

-

Architectural Phase

Our refined design process ensures the meticulous customization of the Axes Sky Perforation system. Detailed design and shop drawings are meticulously prepared thereafter, inviting your thorough review, input, and ultimate approval. Your involvement guarantees the delivery of a final product that precisely reflects your vision and requirements.

-

Manufacturing Specification

Upon your design approval, we commit to a meticulous process to encompass every final detail. Our skilled team works diligently to craft comprehensive, easily interpretable, and highly detailed shop drawings, guaranteeing precision and accuracy at every stage. Your vision directs our actions, and we exhaust all efforts to transform it into tangible perfection.

-

Engineering Appraisal

Whether collaborating with your in-house engineering experts or utilizing our skilled engineering team, every Graphic Perforation project undergoes a detailed assessment before manufacturing begins. Our main priority is to conduct a meticulous evaluation to ensure smooth compliance with design specifications and project needs, thereby ensuring the achievement of the highest quality results.

-

Modernized Production

At the heart of our precision-driven approach are our modern facilities, advanced equipment, and skilled workforce. Through the integration of customized software solutions and the adoption of advanced manufacturing techniques, we ensure the production of precise, premium-grade products. This unwavering commitment to precision enhances your satisfaction and raises the standard of your final installations.

-

Transit and Handover

Our dedicated team manages every logistical aspect from initiation to completion. Through the application of stringent quality control measures, we meticulously organize the part crating sequence, ensuring precise fastener placement. This meticulous attention to detail guarantees the secure packaging of your product and its timely delivery without any damage.

-

Implementation

We're ready to effortlessly facilitate your connection with our roster of trusted installers. Our dedicated team of project managers will be at your service, offering support and guidance throughout your journey. Ensuring your satisfaction and the success of your project are our utmost priorities.