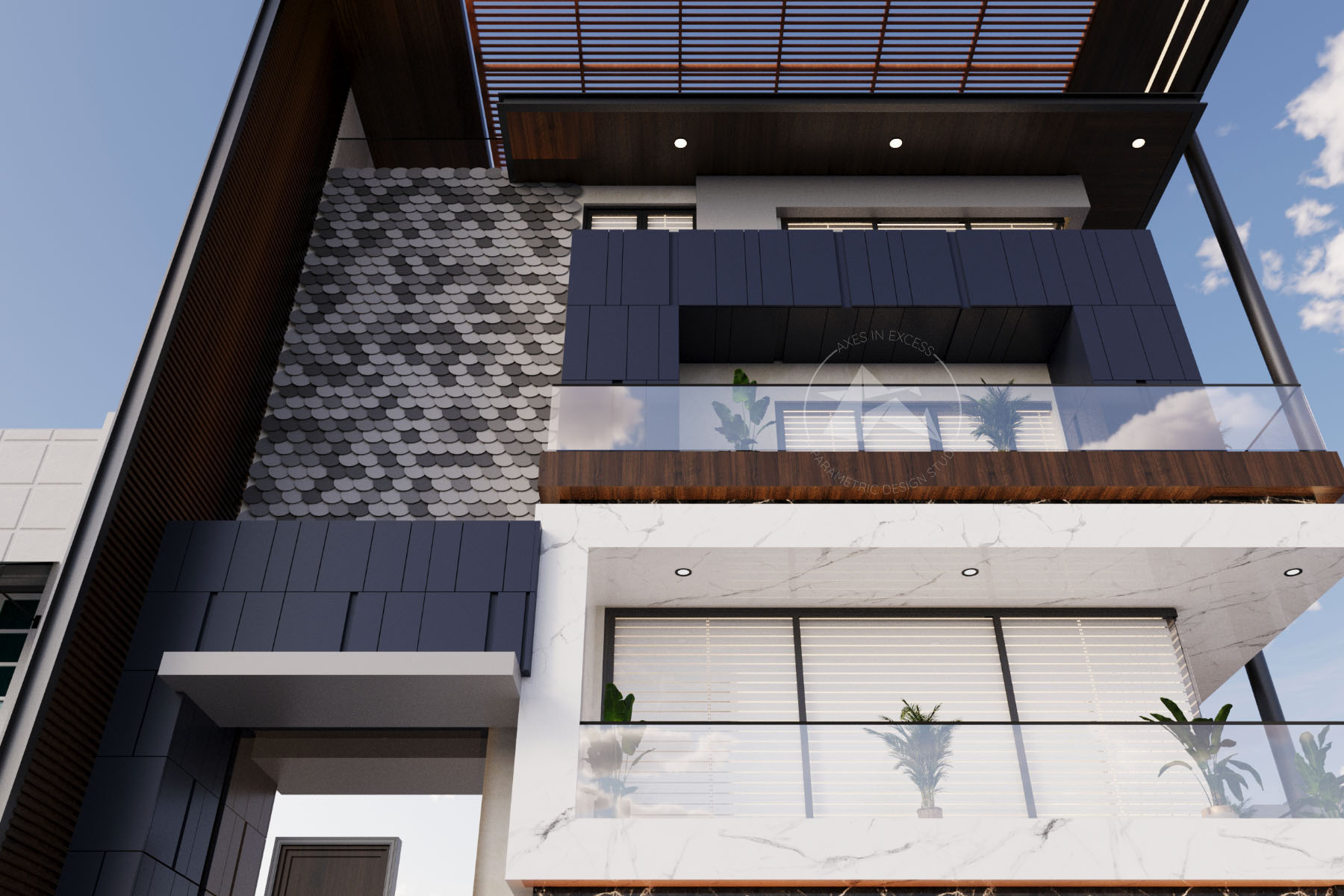

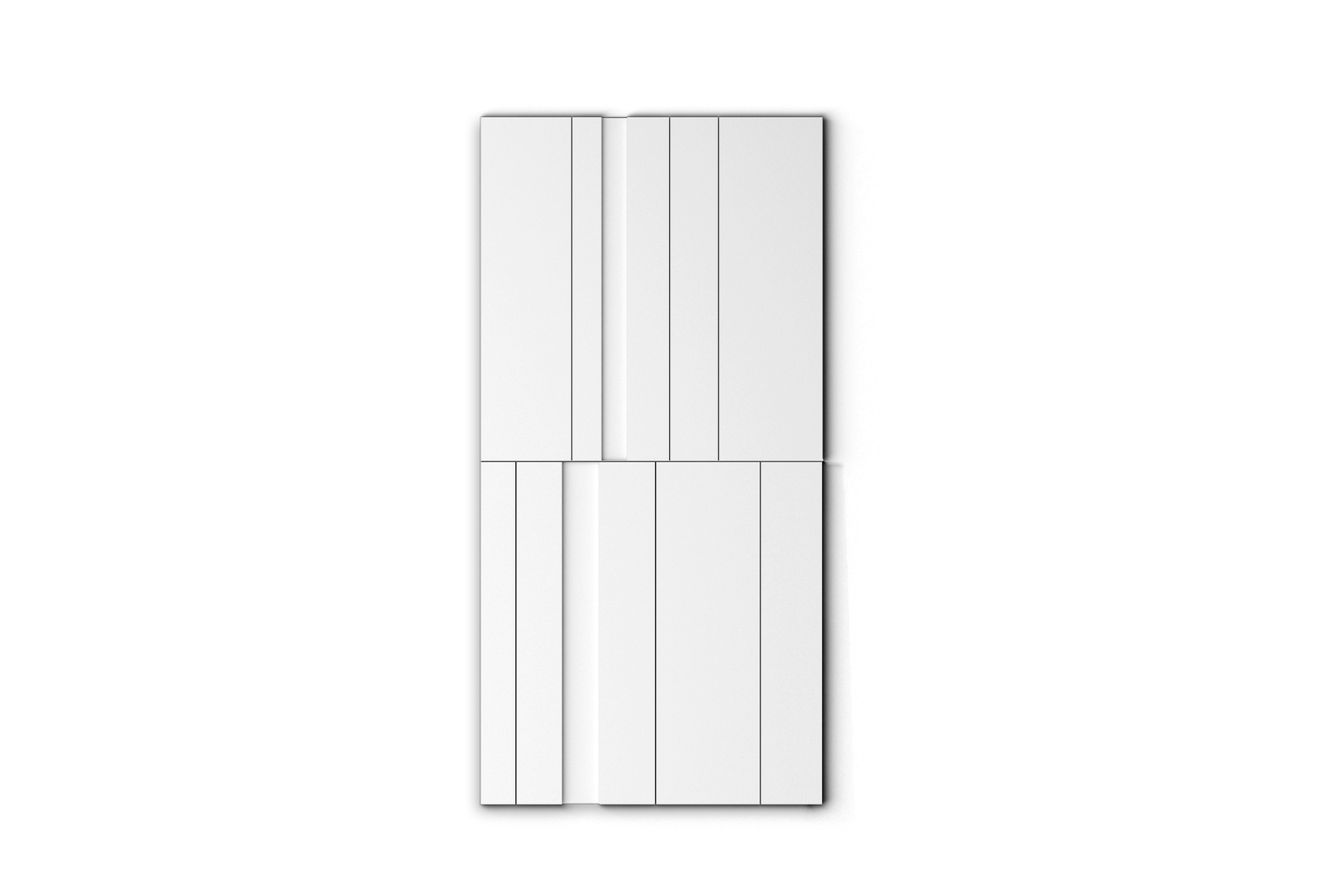

Perforation - Solid Cassette Panel

Axes in Excess's Solid panel full metal jacket enhances the longevity of the building, while also distinguishing it with its exceptional finish and form.

Key Features

-

Impeccable Flatness and Resilience

Axes panels excel in both flatness and strength, raising the industry bar. Our aluminum panels are 50% thicker than those of competitors, ensuring superior quality and enduring performance.

-

Versatile and Plug-and-Play Solutions

With Axes panels, you get scalable, seamlessly tileable preconfigured solutions suited to various criteria.

Materials & Finishes

Powder Coated Aluminum - Single Color

Aluminum

Powder Coated Aluminum - Premium Metallic Finish

Aluminum

Powder Coated Aluminum - Special Shades

Aluminum

Powder Coated Aluminum - Premium Wood Textures

Aluminum

Anodized Finish - Aluminum

AluminumHow to Specify:

-

Quotation Assignment

Our devoted sales support team rapidly gathers all essential project data, enabling a thorough assessment of crucial project factors. We prioritize efficiency and precision above all else.

-

Creation Stage

The Axes solid system is meticulously fashioned and personalized using our proven design approach. Subsequently, detailed design and shop drawings are meticulously formulated for your thorough assessment, contribution, and final authorization. Your active participation ensures the delivery of a final product that impeccably corresponds to your vision and requirements.

-

Production Detailing

Upon receipt of your design confirmation, we embark on a thorough process to encapsulate each final aspect. Our proficient team diligently creates comprehensive, easily understandable, and highly detailed shop drawings, ensuring precision and accuracy every step of the way. Your vision guides our actions, and we leave no stone unturned in transforming it into tangible excellence.

-

Design Inspection

Whether working alongside your internal engineering resources or leveraging our proficient engineering team, every Graphic Perforation project undergoes a comprehensive evaluation prior to manufacturing initiation. We prioritize a meticulous assessment to ensure perfect synchronization with design parameters and project necessities, thereby ensuring the attainment of the highest quality standards.

-

Innovative Production

Our commitment to precision-driven outcomes is bolstered by our state-of-the-art facilities, advanced equipment, and skilled workforce. Through the integration of custom software solutions and the application of advanced manufacturing techniques, we ensure the production of precise, high-quality products. This dedication to precision not only adds value to your business but also enhances the standard of your completed installations.

-

Shipment and Receipt

Our dedicated team oversees all logistics, ensuring a seamless process from start to finish. With strict adherence to quality control measures, we intricately coordinate the part crating sequence, meticulously placing fasteners. This methodical approach ensures that your product is packaged securely and arrives at its destination without delay, exactly as planned.

-

Setting up

We're primed to effortlessly link you with our network of esteemed installers. Our dedicated team of project managers will walk alongside you, offering support and direction throughout your endeavor. Your contentment and the triumph of your project are our primary concerns.