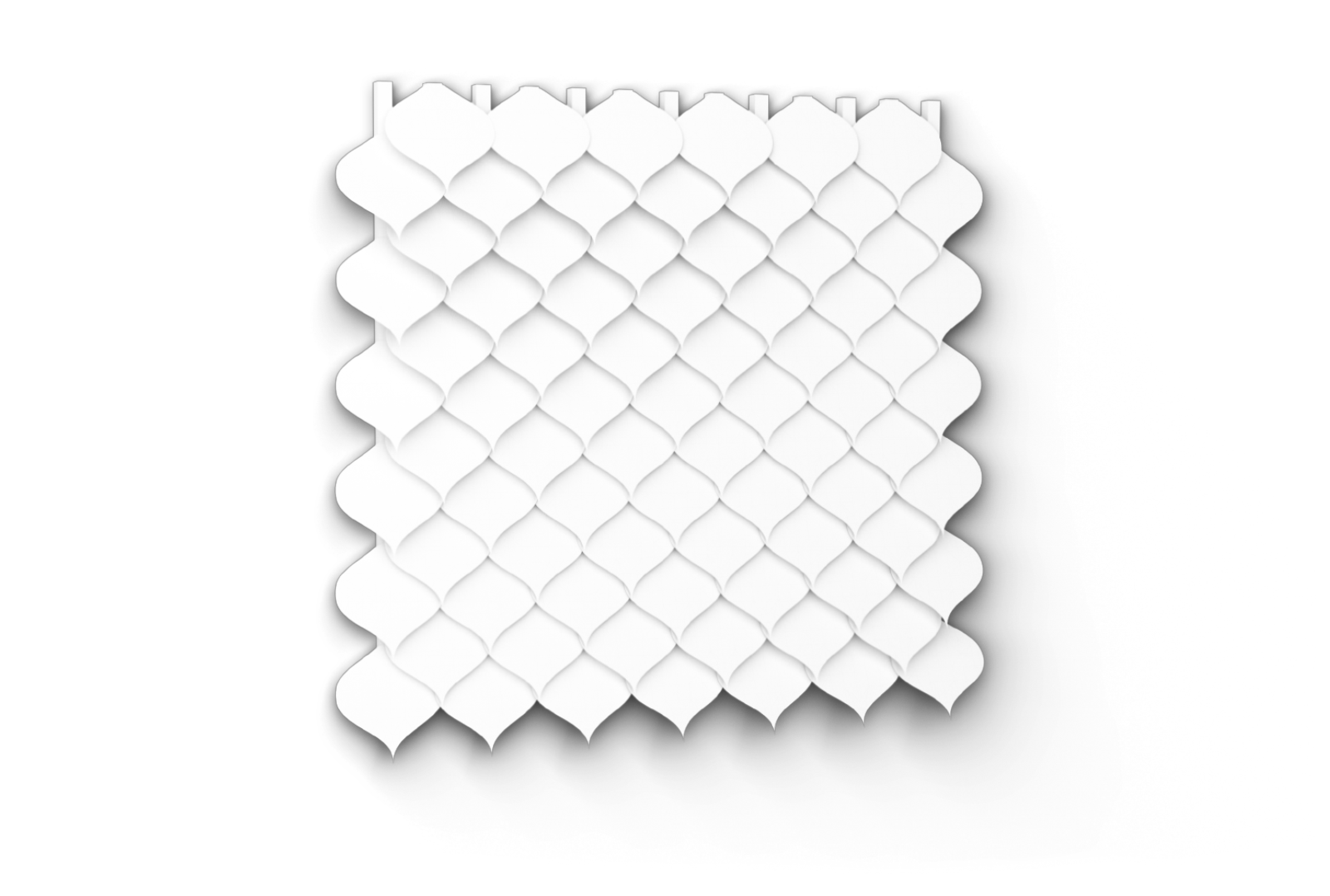

Pixelate Screen - Leaf-Petals

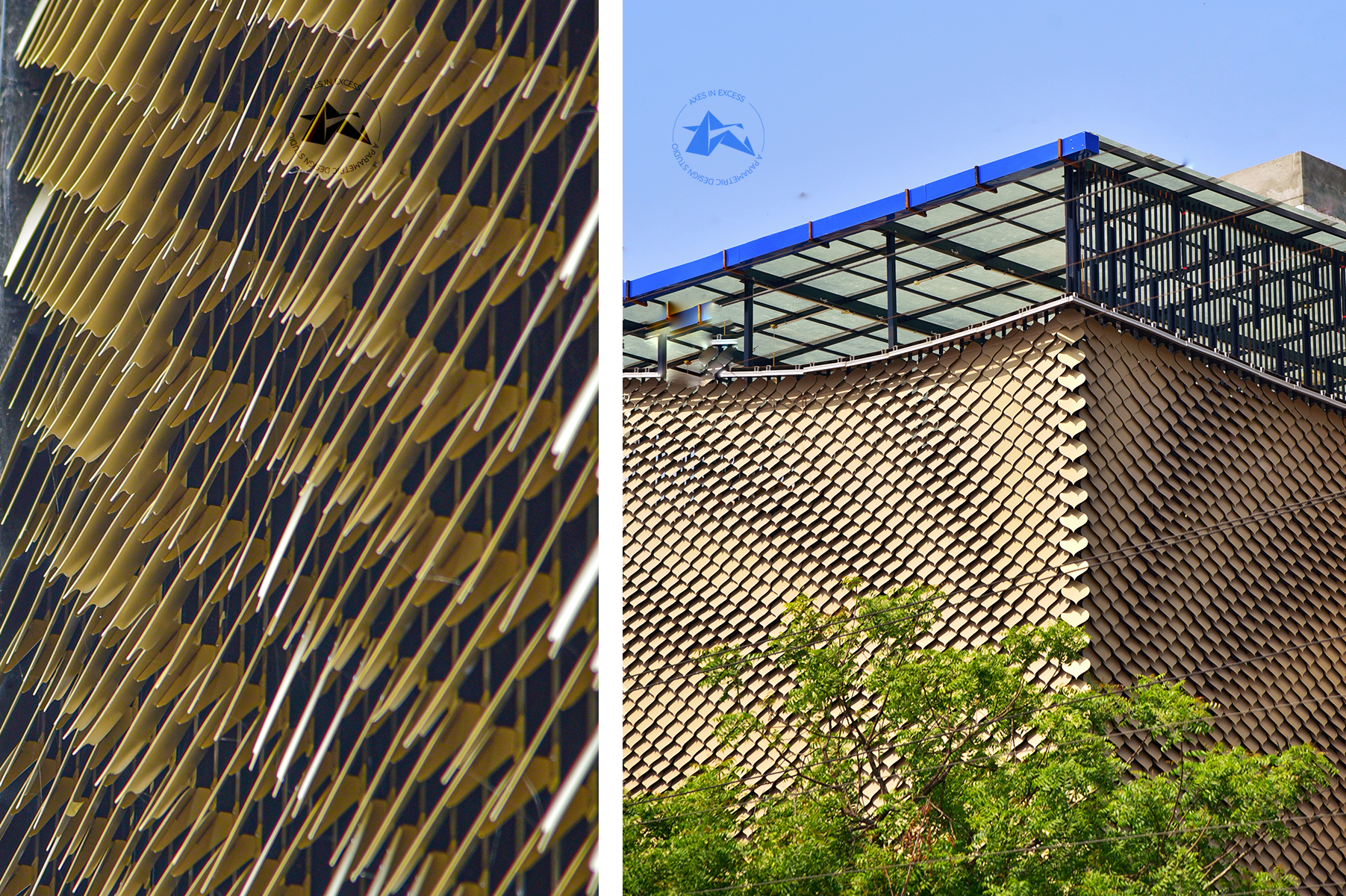

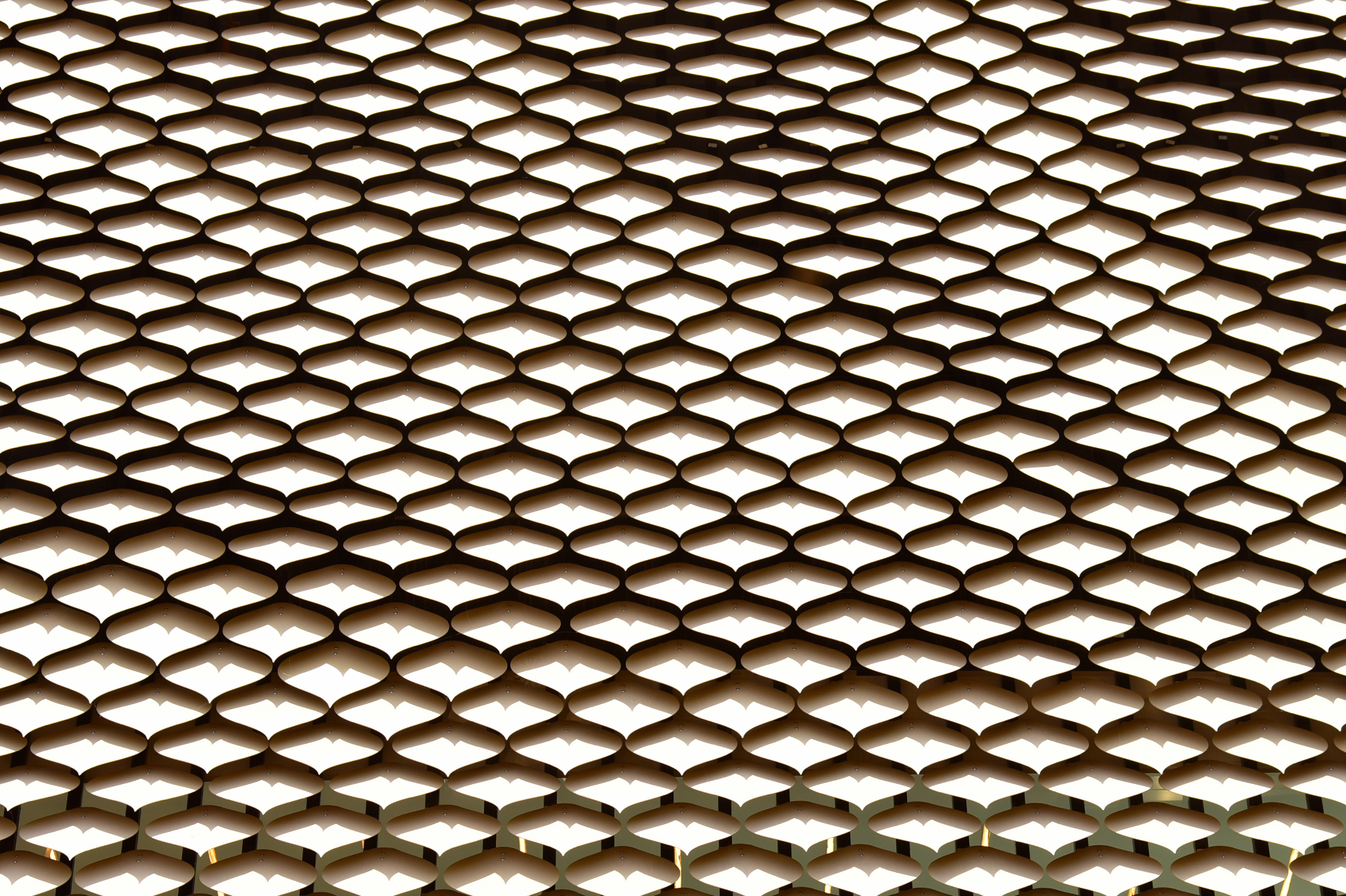

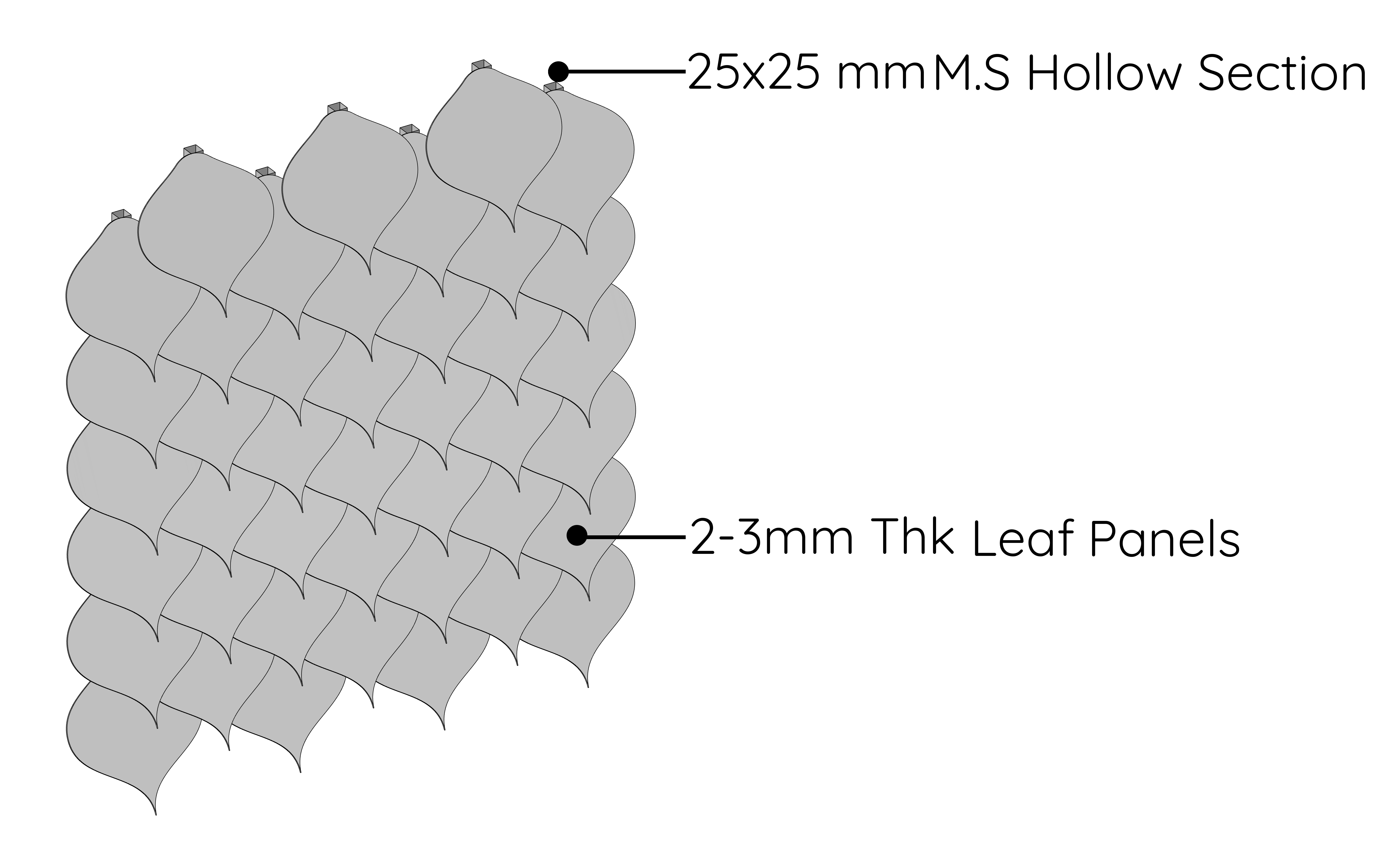

The parametric design facilitates adaptive leaf-petals geometry, enabling the facade screen to respond to diverse environmental and functional factors. The screen's patterns and shapes can be dynamically adjusted based on variables such as solar orientation, shading needs, wind flow, or aesthetic preferences. This adaptability significantly enhances the functionality and performance of the facade screen.

Key Features

-

Parametric Design Adaptability

Aluminum parametric facade screens showcase exceptional design flexibility, leveraging advanced principles that empower architects to craft bespoke, aesthetically pleasing patterns and shapes.

-

Dynamic Geometry and Versatile Patterns

Through parametric design, the facade screen adopts adaptive geometry, reacting to environmental factors such as solar orientation, shading requirements, wind flow, and aesthetics. This enhances both functionality and performance.

-

Lightweight Building

Aluminum's lightweight nature makes it an ideal choice for facade screens, improving material efficiency while maintaining strength. Its easy handling, installation, and reduced structural load on buildings further enhance its appeal.

-

Recyclability

Aluminum, renowned for its sustainability and recyclability, perfectly aligns with eco-friendly design principles. Incorporating recyclable aluminum in a parametric facade screen enhances sustainability, contributing to greener building solutions.

Materials & Finishes

Powder Coated Aluminum - Single Color

Aluminum

Powder Coated Aluminum - Premium Metallic Finish

Aluminum

Powder Coated Aluminum - Special Shades

Aluminum

Anodized Finish - Aluminum

AluminumHow to Specify:

-

COST ESTIMATION

Our dedicated sales support team efficiently gathers all essential project data, ensuring a thorough consideration of critical project factors. Efficiency and precision are our top priorities.

-

PLANNING PHASE

The Axes Pixelate system is meticulously tailored and customized through our established design process. Subsequently, detailed design and shop drawings are meticulously crafted for your thorough review, input, and ultimate approval. Your involvement ensures a final product that perfectly aligns with your vision and requirements.

-

PRODUCTION SPECIFICATIONS

Upon receiving your design approval, we embark on a meticulous process to capture every final detail. Our skilled team works diligently to craft comprehensive, easy-to-understand, and highly specific shop drawings, ensuring precision and accuracy at every step. Your vision guides us, and we leave no stone unturned in translating it into tangible excellence.

-

ENGINEERING ASSESSMENT

Whether working alongside your in-house engineering resources or utilizing our own skilled engineering team, every Graphic Perforation project undergoes a meticulous evaluation before manufacturing begins. We prioritize this comprehensive assessment to ensure seamless alignment with design specifications and project requirements, thereby guaranteeing the delivery of the highest quality outcomes.

-

PRECISION PRODUCTION

At the heart of our precision-driven outcomes are our state-of-the-art facilities, cutting-edge equipment, and skilled personnel. Through the integration of custom software and the utilization of advanced manufacturing techniques, we guarantee the delivery of precise, high-quality products. This commitment to precision not only benefits you and your esteemed clients but also elevates the standard of your finished installation.

-

LOGISTICS AND DELIVERY

From the initiation to the completion of your project, our dedicated team oversees every aspect of logistics. We implement stringent quality control measures, meticulously organizing the part crating sequence down to the placement of fasteners. This meticulous approach ensures that your product is securely packed and arrives at its destination undamaged and precisely on schedule.

-

INSTALLATION

We're ready to seamlessly connect you with our network of trusted installers. Our dedicated team of project managers will be by your side, providing support and guidance throughout your journey. Your satisfaction and project success are our top priorities.